Welcome to My Blog! 🌟

Before we dive into the content, let’s stay connected! Join me on my social media platforms where I share exclusive insights, engage with our amazing community, and post regular updates. Here’s how you can connect with me:

📘 Facebook: Follow Me on Facebook

Now, let’s embark on this journey together. I hope you find the content here insightful, engaging, and most importantly, valuable. Let’s explore, learn, and grow together! 🚀

Feel free to share your thoughts and feedback in the comments or on my social media—I’d love to hear from you! 😊

Table of Contents

Introduction

When it comes to choosing materials for concrete formwork and construction projects, form plywood stands out as a preferred choice among smart buyers worldwide. Its excellent physical properties, durability, and ease of use make it indispensable in modern construction. Form plywood offers not only reliability and cost-effectiveness but also sustainable benefits that align with green building principles.

In this blog, we will explore why form plywood continues to dominate the construction materials market, what qualities buyers should look for, and how Shandong Panel International Trade Co., Ltd. provides high-quality solutions tailored for diverse construction needs. Whether you are a contractor, builder, or procurement specialist, understanding form plywood’s benefits will empower you to make informed purchasing decisions.

What Is Form Plywood and Why It Matters for Smart Buyers

Definition and Core Features of Form Plywood

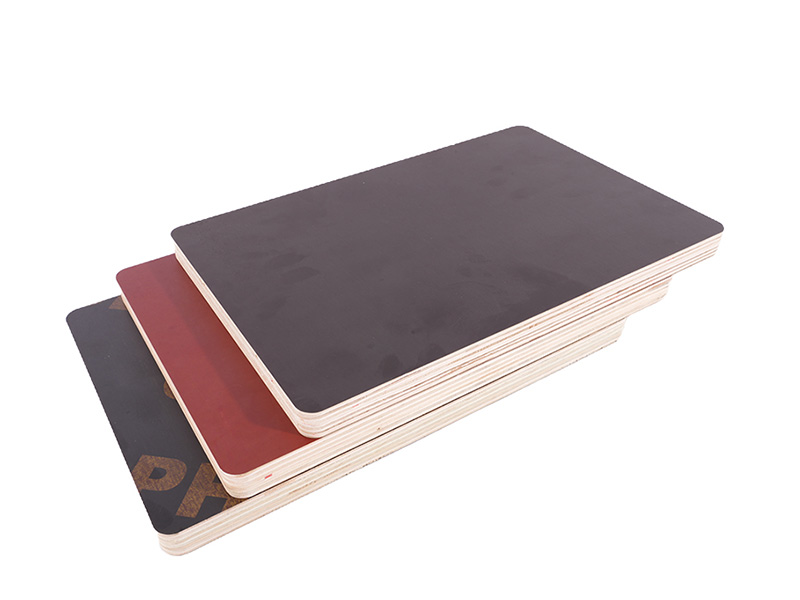

Form plywood, commonly referred to as film faced plywood, is a specialized engineered wood product designed specifically for use in concrete formwork and construction applications. It is manufactured by bonding multiple layers of hardwood veneers—typically poplar or birch—using waterproof adhesives. This multi-layered core provides excellent strength, dimensional stability, and resistance to warping or splitting under heavy loads and varying weather conditions.

A distinctive feature of form plywood is its phenolic film coating applied to both surfaces. This coating creates a smooth, hard, and highly durable layer that is water-resistant, corrosion-resistant, and capable of withstanding abrasion from repeated concrete casting. The phenolic film also ensures easy demoulding, preventing concrete from sticking to the surface and allowing the plywood to be reused multiple times without significant degradation. The combination of high-density core materials and the phenolic film results in a product that balances robustness with functional versatility—key attributes highly valued by smart buyers in the construction industry.

Advantages of Form Plywood in Construction

Form plywood offers several advantages that make it the preferred choice for professionals and savvy buyers alike:

- Superior Strength and Stability: Thanks to its multi-layered hardwood core bonded with waterproof glue, form plywood can endure the heavy pressure exerted by wet concrete during pouring and setting. This prevents deformation, cracking, or warping that could compromise structural integrity or lead to costly project delays.

- Reusable and Cost-Effective: Unlike untreated plywood or other temporary formwork materials, form plywood’s phenolic coating allows it to be reused multiple times—often 10 to 15 cycles or more—without losing surface quality. This reusability translates directly to cost savings and reduced material waste, appealing to buyers focused on maximizing their budget and environmental responsibility.

- Smooth Concrete Finishes: The phenolic film surface ensures a high-quality, smooth concrete finish, reducing the need for additional surface treatments or repairs. This efficiency not only speeds up project timelines but also enhances the final aesthetic and structural performance of concrete elements.

- Water and Weather Resistance: Construction sites often face challenging environmental conditions, including rain, humidity, and temperature fluctuations. The water-resistant coating and strong adhesives used in form plywood protect it from moisture damage and deterioration, ensuring consistent performance even on long-term projects.

- Reduced Labor and Maintenance: Because of its durability and ease of cleaning, form plywood requires less maintenance between uses. Labor costs related to replacing damaged formwork or extensive surface repairs are significantly lowered, allowing construction teams to focus on other critical tasks.

Overall, the combination of these features makes form plywood a strategic investment for buyers who prioritize quality, durability, and long-term value in their construction materials. It meets the demanding needs of various projects—from residential foundations to large-scale commercial and infrastructure works—providing reliability and peace of mind throughout the build.

Mid-Article Table: Comparing Form Plywood to Alternative Materials

| Material Type | Water Resistance | Durability | Surface Smoothness | Reusability | Cost Efficiency | Typical Applications |

|---|---|---|---|---|---|---|

| Form Plywood | Excellent | High | Very Smooth | Multiple uses | High | Concrete formwork, foundations |

| Untreated Plywood | Poor | Moderate | Rough | Limited | Low | Temporary uses, non-structural |

| OSB (Oriented Strand Board) | Moderate | Moderate | Rough | Limited | Moderate | Sheathing, flooring |

| Steel Form Panels | Excellent | Very High | Smooth | Very high | High | Repetitive use, industrial |

This table shows why form plywood is a smart balance of cost, performance, and versatility compared to other common formwork materials.

Key Considerations When Buying Form Plywood

Quality of Core Material and Adhesive

The core material of form plywood plays a decisive role in determining its overall strength, durability, and longevity. High-density hardwood cores such as poplar and birch are widely recognized for their excellent load-bearing capacity and resistance to deformation under pressure. These hardwood layers are carefully selected and processed to ensure uniformity and consistency, which minimizes the risk of warping, splitting, or delamination during use.

Equally important is the adhesive used to bond these layers. Waterproof glue that meets or exceeds international quality and environmental standards is essential to maintain the structural integrity of the plywood, especially in wet or humid construction environments. The glue not only holds the layers together firmly but also prevents moisture infiltration, which can lead to swelling and weakening of the board. Smart buyers pay close attention to suppliers who transparently share details about the adhesives used, including certifications such as CARB (California Air Resources Board) compliance, which guarantees low formaldehyde emissions and environmental safety.

Thickness and Size Options

Form plywood comes in a range of thicknesses to suit different construction demands, typically between 9mm and 21mm. The choice of thickness depends largely on the type of concrete structure, the expected load, and the support framework used in the formwork system. Thicker plywood panels offer greater strength and are preferred for heavy-duty applications such as large columns, beams, and high-rise foundations, while thinner panels can be suitable for lighter or temporary structures.

Standard sizes often include 1220x2440mm and 1250x2550mm, but customization is frequently available for unique project requirements. Buyers who understand their project’s specific needs opt for sizes and thicknesses that optimize material usage and minimize waste. Additionally, selecting the right thickness also affects the weight of the plywood, which in turn impacts ease of handling and transportation—factors that contribute to labor efficiency and overall project cost.

Surface Coating and Film Type

The surface coating, usually a phenolic resin film, is what primarily distinguishes form plywood from regular plywood. This film coating is available in different colors, with black and brown being the most common. The color often correlates with the specific resin composition and thickness of the film, which affects durability and performance.

High-quality phenolic films provide excellent resistance against corrosion, abrasion, and moisture, allowing the plywood to be reused multiple times without significant surface degradation. The durability of the film coating directly impacts the number of reuse cycles the plywood can endure—an important consideration for buyers aiming to maximize return on investment. Moreover, the quality of the film influences the smoothness of the concrete finish, reducing defects such as voids, bubbles, or surface roughness.

When purchasing form plywood, buyers should inquire about the film’s thickness (measured in grams per square meter) and resistance properties to ensure the product meets their specific construction standards and expectations.

Supplier Reliability and Production Standards

A reputable and reliable supplier is a cornerstone of a successful purchase. Buyers should select companies that maintain strict quality control protocols throughout the manufacturing process. This includes raw material selection, adhesive application, pressing conditions, and final inspection of finished plywood.

Suppliers offering OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services provide added flexibility for buyers who need customized solutions tailored to their projects. It is also essential to verify that the supplier possesses certifications demonstrating compliance with international environmental, safety, and quality standards, such as ISO 9001, FSC (Forest Stewardship Council), and CE marking.

An established supplier will have a mature and efficient supply chain, enabling shorter delivery times and consistent product availability—critical factors for construction schedules. Buyers should also consider after-sales support, warranty terms, and the supplier’s reputation for customer service, as these elements contribute to a smoother purchasing experience and long-term partnership.

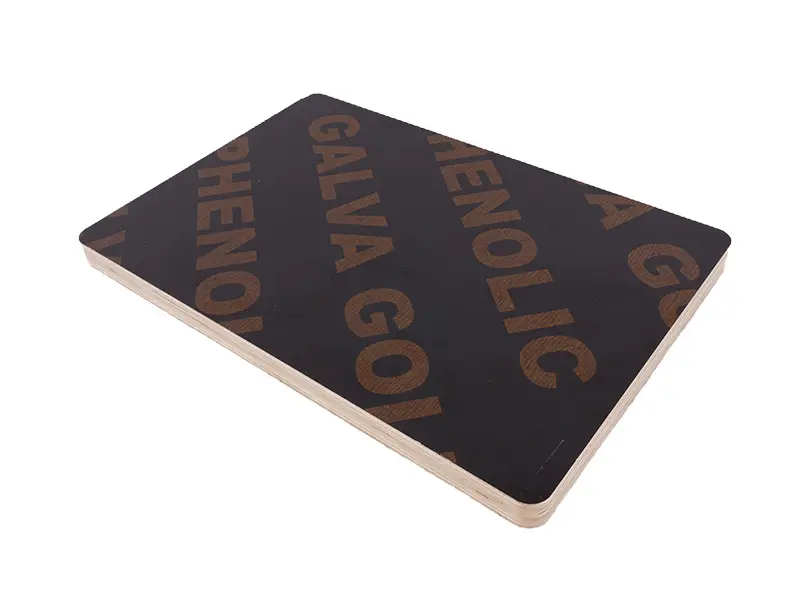

About Shandong Panel International Trade Co., Ltd. and Our Form Plywood Products

Shandong Panel International Trade Co., Ltd. is a leading manufacturer and exporter of decorative and construction panel materials. Founded on the principles of innovation and quality-first, the company offers a comprehensive product range including polyester acoustic panels, WPC boards, film faced plywood, commercial plywood, and UV panels.

Our film faced plywood is engineered to meet the highest standards for concrete formwork applications. Manufactured from renewable materials and coated with phenolic resin films, our plywood ensures superior water resistance, smooth finishes, and long-lasting durability. We support customization to fit your project requirements and offer a reliable supply chain with efficient delivery.

With over 300 customers worldwide and more than 5,000 tons exported annually, Shandong Panel International Trade Co., Ltd. is committed to sustainable development and customer satisfaction. We continuously improve product quality and provide comprehensive services to help smart buyers make the best choice.

Conclusion

Form plywood offers a unique combination of performance, durability, and cost-effectiveness that makes it the preferred material for construction professionals globally. Its strong core, water-resistant surface, and excellent reusability provide smooth concrete finishes and reduce labor and material costs. Choosing form plywood from a trusted supplier like Shandong Panel International Trade Co., Ltd. guarantees quality, innovation, and reliable service.

Whether you manage commercial projects, infrastructure development, or residential construction, investing in high-quality form plywood ensures long-term value and project success. Don’t compromise on material quality—make the smart choice today.

Contact Shandong Panel International Trade Co., Ltd. to learn more about our form plywood solutions and how we can support your next project. Let us help you build with confidence and precision.

FAQ

What thickness of form plywood is best for heavy-duty construction?

Typically, 15mm to 21mm thicknesses are preferred for heavy concrete loads, but the choice depends on your project specifications and load requirements.

How many times can form plywood be reused?

High-quality form plywood with phenolic film coating can be reused 10 to 15 times or more, depending on site conditions and handling.

Is form plywood environmentally friendly?

Yes, form plywood is often made from renewable wood resources and uses eco-friendly adhesives and coatings, aligning with green construction practices.

Can form plywood be customized to specific sizes?

Yes, suppliers like Shandong Panel International Trade Co., Ltd. provide OEM/ODM services and can produce plywood in various sizes and thicknesses according to customer needs.

How should form plywood be maintained for maximum lifespan?

Store plywood in a dry, ventilated area; avoid prolonged exposure to water; clean surfaces after use; and inspect regularly for damage before reuse.