Table of Contents

Introduction

Formwork plays a crucial role in determining the strength, durability, and precision of any concrete structure. Among the many choices in the construction world, concrete plywood has emerged as a popular alternative to traditional formwork methods. Understanding the core differences between concrete plywood and conventional formwork systems is essential for project managers, builders, and procurement teams aiming for cost-effectiveness, speed, and sustainability.

As a company committed to quality and innovation, Shandong Panel International Trade Co., Ltd. integrates cutting-edge research, production, and global service to deliver top-tier building materials. In this blog, we explore the five most defining contrasts between concrete plywood and traditional formwork systems, helping you make informed decisions that elevate project outcomes.

1. Material Composition and Structure

Concrete Plywood: Engineered Efficiency for Modern Construction

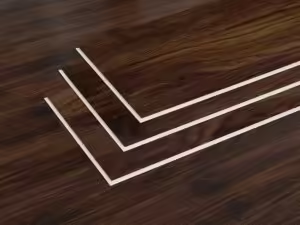

Concrete plywood, also known as film-faced plywood, is a specially engineered panel made by laminating multiple thin wood veneers with high-performance adhesives. These layers are bonded under heat and pressure, and the exterior surfaces are treated with phenolic or melamine resin coatings. This treatment renders the panels water-resistant, smooth, and highly resistant to the alkaline nature of concrete.

The result is a formwork panel that offers excellent dimensional stability and is far less prone to warping, delamination, or surface damage compared to untreated wood. Concrete plywood can maintain its form even after repeated use, making it a preferred choice for contractors seeking balance between performance and cost-efficiency.

At Shandong Panel International Trade Co., Ltd., our concrete plywood products are manufactured in accordance with international quality and safety standards. Using advanced resin systems and precise pressing techniques, we ensure each panel meets the mechanical and environmental requirements for demanding job sites around the world.

Traditional Formwork: Heavier and More Labor-Intensive Systems

By contrast, traditional formwork often relies on materials like raw timber, steel, or aluminum. While structurally strong, these systems are typically heavier and less user-friendly. Steel and aluminum require mechanical lifting equipment and skilled labor for installation. Their rigidity can be a benefit in large-scale infrastructure but introduces inefficiencies in smaller or more complex construction projects.

Wooden plank-based traditional formwork lacks the engineered consistency of concrete plywood, making it prone to defects, leaks, and a shorter lifespan. It also demands more material and labor adjustments onsite, increasing the time and complexity of formwork preparation.

2. Durability and Reusability

Concrete Plywood: A Reliable and Cost-Efficient Performer

One of the most praised characteristics of concrete plywood is its reusability. With proper care and maintenance, high-grade concrete plywood panels can be reused 20 to 40 times. This makes them exceptionally economical for medium to large-scale construction projects. The non-stick resin surface allows for clean removal after curing, reducing the risk of concrete adhesion and thus preventing surface damage.

At Shandong Panel, our commitment to optimal cost-performance is reflected in our use of superior waterproof resins and durable core materials. These enhancements increase abrasion resistance and minimize edge chipping or delamination, even under high-pressure pours and harsh job site conditions.

Contractors benefit from reduced material replacement rates, better surface finishes, and improved formwork cycle efficiency—all of which contribute to lower overall costs.

Traditional Formwork: Robust but Limited in Flexibility

While metal formwork systems may offer longer reuse lifespans—sometimes upwards of 100 uses—they come with significant trade-offs. The high initial investment, increased installation labor, and expensive repair needs make them less practical for varied-scale projects.

Additionally, traditional timber formwork generally has lower reuse potential and is highly susceptible to moisture, which accelerates deterioration. This leads to more frequent replacements and higher waste volumes.

3. Installation and Handling Time

Concrete Plywood: Lightweight Advantage for Job Site Agility

One of the primary advantages of concrete plywood is its ease of handling. Thanks to its lightweight structure, fewer workers and minimal equipment are needed for transportation and installation. This is particularly important in mid-rise buildings, housing projects, or formwork applications where agility and speed are key performance indicators.

At Shandong Panel, we understand the importance of logistics in construction timelines. That’s why our concrete plywood is available in a variety of customizable sizes and thicknesses, reducing onsite cutting and waste. With our mature supply chain and fast delivery system, project managers can rely on timely availability and efficient formwork operations.

Traditional Formwork: Installation Challenges and Skilled Labor Dependency

Unlike concrete plywood, steel or aluminum systems typically require heavy machinery for lifting and aligning panels. The complex joint systems and strict tolerances also mean these materials often demand highly trained installers. Any misalignment or error during setup could result in poor concrete curing, leaks, or defects—requiring costly fixes or delays.

In contrast, concrete plywood panels can be quickly adjusted, cut, or replaced, giving construction teams greater flexibility and reducing labor hours on the ground.

4. Surface Finish and Post-Pour Quality

Concrete Plywood: Achieving a Superior Architectural Finish

One of the reasons why architects and contractors prefer concrete plywood is its ability to produce smooth, clean concrete surfaces. The phenolic-coated finish of concrete plywood reduces the need for post-casting surface treatment like plastering or grinding. This is especially valuable for exposed concrete applications in modern architectural designs.

Shandong Panel’s concrete plywood is engineered for uniform thickness and surface flatness, ensuring minimal variation between panels. Whether used for columns, walls, or slabs, our panels deliver visually pleasing finishes with tight dimensional accuracy, helping projects maintain design intent and minimize finishing labor.

Traditional Formwork: Functional but Often Less Refined

Metal-based formwork systems, while durable, can sometimes leave imprints, grooves, or uneven textures on the concrete surface. In structural projects where aesthetics are not a concern, this may be acceptable. However, for decorative facades or interiors, these imperfections often necessitate additional treatments, increasing cost and construction time.

Timber also tends to absorb water from the concrete mix, which can cause discoloration or inconsistent curing. This makes concrete plywood a more consistent and reliable alternative for achieving architectural-grade results.

5. Cost and Environmental Impact

Concrete Plywood: Economical, Sustainable, and Scalable

Concrete plywood offers a unique combination of affordability and eco-consciousness. It requires less energy to manufacture than metal formwork and is often produced from fast-growing, sustainably harvested wood sources. Moreover, the ability to reuse panels multiple times significantly reduces waste.

At Shandong Panel International Trade Co., Ltd., our environmental commitment is reflected in every part of our manufacturing process. We use low-VOC, formaldehyde-free adhesives, source our wood responsibly, and operate energy-efficient production lines. This ensures our concrete plywood not only meets technical requirements but also aligns with modern green building standards.

Traditional Formwork: Higher Cost, Heavier Footprint

Steel and aluminum systems are resource-intensive to produce and transport. Their weight increases carbon emissions in shipping, and their disposal poses long-term environmental concerns. Once damaged, these materials are expensive to repair or recycle. Traditional timber formwork, when untreated, often ends up as waste after limited use cycles.

For contractors aiming to reduce project costs and environmental impact, concrete plywood presents a smarter and more sustainable solution.

Concrete Plywood vs Traditional Formwork: Feature Comparison Table

| Feature | Concrete Plywood | Traditional Formwork |

|---|---|---|

| Material Type | Engineered wood with resin surface | Steel, aluminum, or untreated timber |

| Weight | Lightweight | Heavy |

| Reusability | 20–40 times depending on care | 100+ times (steel/aluminum) |

| Installation Time | Fast, minimal labor | Slower, needs skilled workers |

| Surface Finish | Smooth, uniform | Often textured or patterned |

| Environmental Friendliness | High – sustainable wood + low-VOC resins | Moderate to Low |

| Cost Efficiency | High | Lower for very large-scale, repeated use |

Conclusion

Both concrete plywood and traditional formwork systems have their merits. The right choice depends on the project scale, budget, aesthetic requirements, and available labor. However, for developers seeking speed, flexibility, and a smooth finish without sacrificing structural integrity, concrete plywood presents a compelling solution.

At Shandong Panel International Trade Co., Ltd., our commitment to quality-first development and innovation ensures that our concrete plywood products deliver not only performance but also value. Whether for mid-rise buildings, commercial spaces, or infrastructure development, our plywood solutions are built to perform across a range of applications.

Through efficient logistics, customizable specifications, and strict quality control, we are redefining expectations in modern construction materials—empowering clients around the world with better building outcomes.

FAQ

What makes concrete plywood better than standard wood panels?

Concrete plywood is engineered for construction with multiple resin-treated layers, making it resistant to moisture, warping, and deformation. This ensures better performance during concrete pours and longer lifespan.

Can Shandong Panel customize plywood for specific dimensions?

Yes. Our team supports custom orders for size, thickness, and surface treatments, ensuring each panel aligns with your project’s design needs and construction tolerances.

How many times can I reuse your concrete plywood?

Depending on maintenance and application, our concrete plywood can be reused up to 40 times, offering excellent return on investment.

Does your plywood meet international quality standards?

Absolutely. All Shandong Panel products, including our concrete plywood, are produced under rigorous quality control systems and meet or exceed international benchmarks.

How fast can you deliver to international job sites?

Thanks to our mature supply chain and export team, we offer short lead times, fast communication, and full OEM/ODM support for overseas orders.

For more information on Shandong Panel’s full product line—ranging from concrete plywood to SPC plastic flooring—reach out to our team or request a catalog today.

Let’s Keep in Touch! 🌟

Thanks for reading—I’m glad you joined me on this journey!

If you found this content valuable, insightful, or thought-provoking, I’d love to hear your thoughts.

📘 Follow me on Facebook for exclusive tips, behind-the-scenes insights, and community discussions.

👉 Click here to connect

Feel free to share your feedback or questions in the comments or on social media—I’m always here to chat.

Let’s keep exploring, learning, and growing—together! 🚀😊