Welcome to My Blog! 🌟

Before we dive into the content, let’s stay connected! Join me on my social media platforms where I share exclusive insights, engage with our amazing community, and post regular updates. Here’s how you can connect with me:

📘 Facebook: Follow Me on Facebook

Now, let’s embark on this journey together. I hope you find the content here insightful, engaging, and most importantly, valuable. Let’s explore, learn, and grow together! 🚀

Feel free to share your thoughts and feedback in the comments or on my social media—I’d love to hear from you! 😊

Table of Contents

Introduction

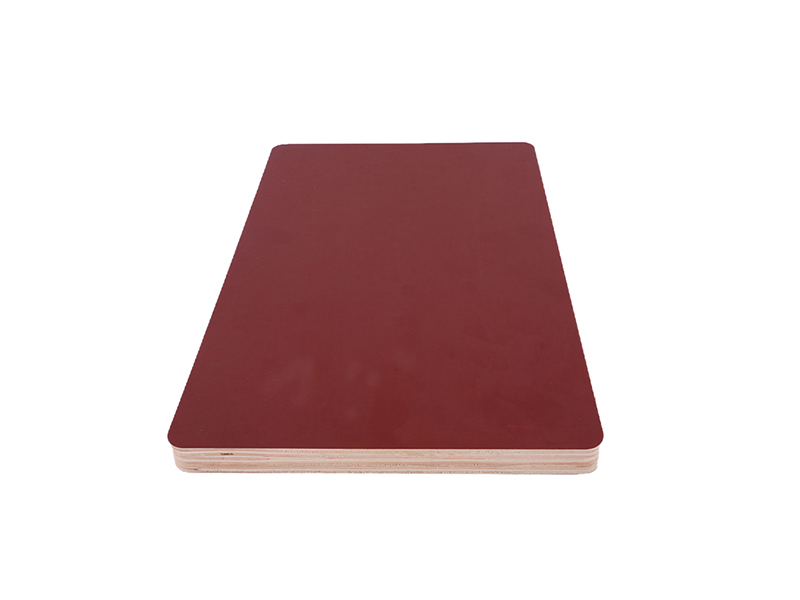

Coloured plywood sheets have gained popularity in interior design, furniture manufacturing, and architectural applications due to their vibrant appearance, flexibility, and ease of installation. These sheets combine aesthetic appeal with functional benefits, making them a preferred choice for many construction and creative projects. However, despite their advantages, coloured plywood sheets are not without issues. Improper handling, substandard materials, or environmental stress can lead to a range of common problems that affect durability, appearance, and usability.

This blog explores five of the most common problems encountered with coloured plywood sheets. By understanding these issues and their root causes, buyers and users can make informed decisions and maintain the quality of their projects over time.

Problem 1: Colour Fading Over Time

One of the most reported issues with coloured plywood sheets is colour fading. This occurs when the vibrant finish of the sheet begins to lose its intensity, making surfaces look dull and aged. The primary reasons behind this problem include:

- UV Exposure: Direct sunlight or fluorescent lighting can break down dyes and pigments.

- Low-Quality Pigments: Budget plywood often uses cheaper dyes that are not UV-resistant.

- Chemical Cleaning Products: Harsh solvents used in maintenance may strip the colour layer gradually.

To mitigate this, it’s essential to choose sheets with UV-resistant coatings and to minimize their exposure to direct sunlight during storage and installation.

Problem 2: Surface Delamination and Peeling

Delamination refers to the separation of veneer layers in the plywood, which compromises both aesthetics and structural performance. In coloured plywood sheets, delamination often includes the peeling of the decorative coloured surface. This can be caused by:

- Moisture Ingress: Poor sealing allows moisture to penetrate, causing adhesives to weaken.

- Inferior Adhesives: Low-grade glue fails under stress or humidity.

- Improper Storage: Exposure to damp conditions during transit or storage accelerates delamination.

Users should ensure the plywood is sealed properly and stored in a dry environment. Opting for moisture-resistant grades can significantly reduce this risk.

Problem 3: Uneven Colour Consistency in Sheets

In large-scale projects, maintaining a consistent visual tone across all surfaces is crucial. Unfortunately, coloured plywood sheets can sometimes suffer from noticeable inconsistencies in colour. These inconsistencies arise due to:

- Batch Variations: Different production batches may have slight variations in pigment tone.

- Application Method: Variations in how colour is applied (spray vs. dip) may result in uneven finishes.

- Surface Absorption Differences: Plywood veneers may absorb dyes differently depending on grain pattern and moisture content.

To avoid this issue, buyers should order from a single batch and verify colour match samples beforehand.

Problem 4: Poor Moisture Resistance in Certain Grades

Despite being a processed wood product, not all coloured plywood sheets are water-resistant. This creates a significant risk in humid or wet environments, where:

- Swelling: The sheet edges absorb moisture, leading to dimensional instability.

- Mould Growth: Prolonged dampness encourages microbial growth.

- Finish Degradation: Moisture can erode the surface colour and texture.

Using marine-grade or water-resistant coloured plywood sheets in high-humidity areas is highly recommended. These sheets are manufactured with better glues and treated cores to resist moisture penetration.

Problem 5: Compatibility Issues with Finishing Products

Coloured plywood sheets often require further treatment, such as lamination, varnishing, or printing. However, not all finishes are compatible with every coloured surface. Problems may include:

- Peeling of Coatings: Finishes fail to adhere properly to pigmented surfaces.

- Colour Bleeding: Some solvents in finishes may dissolve or distort the pigment layer.

- Texture Conflicts: Glossy finishes applied over matte surfaces can cause irregular appearance.

Pre-testing any top-coat or finishing material on a sample piece of plywood can prevent these unwanted outcomes.

Comparison Table: Common Issues and Preventive Measures

| Common Issue | Likely Cause | Preventive Measure |

|---|---|---|

| Colour Fading | UV exposure, low-grade dyes | Use UV-resistant coatings; avoid prolonged sunlight |

| Surface Delamination | Poor adhesive, moisture penetration | Store dry; choose waterproof glues |

| Uneven Colour Consistency | Batch variation, uneven absorption | Order same batch; use pre-matched samples |

| Poor Moisture Resistance | Use of interior-grade materials | Select water-resistant or marine-grade sheets |

| Finishing Compatibility Problems | Chemical reactions, poor surface prep | Pre-test finishing products on a sample |

Conclusion

Understanding the typical challenges associated with coloured plywood sheets empowers users to make better material choices and maintain aesthetic and structural performance over time. From selecting the right grade to implementing correct installation and finishing practices, each decision plays a vital role in determining the outcome of your project.

If you’re sourcing coloured plywood sheets for commercial or residential use, always prioritize quality and supplier transparency. Ask about batch consistency, test certifications, and available moisture-resistant options. These small but significant steps can help avoid costly mistakes and ensure the longevity of your build or product.

FAQ

What makes coloured plywood sheets different from standard plywood?

Coloured plywood sheets differ from standard plywood primarily in their visual and finishing characteristics. While both types share the same core structural composition—thin veneer layers bonded together—the coloured variant is treated with pigments or dyes during or after manufacturing. This coloration process can be achieved by surface laminating, veneering, or even by dye-impregnation techniques that go beyond the surface. The result is a vibrant, pre-finished sheet that eliminates the need for painting or staining after installation.

These sheets offer the same strength, flexibility, and versatility as traditional plywood, but with enhanced aesthetic appeal. This makes coloured plywood sheets a popular choice for modern interior design, cabinetry, retail spaces, and exhibition setups where visual presentation is just as important as durability.

Can coloured plywood sheets be used outdoors?

Coloured plywood sheets can be used outdoors, but only under specific conditions. Not all coloured variants are built to endure weather-related stressors like UV radiation, humidity, and rainfall. If you’re planning to use coloured plywood in exterior applications—such as outdoor signage, furniture, or wall cladding—you must choose sheets that are specifically rated for outdoor use.

Look for marine-grade plywood or those labeled as UV-resistant. These are manufactured using waterproof adhesives and are often treated to withstand sunlight exposure and moisture without fading, delaminating, or warping. For prolonged outdoor performance, you should also consider applying a clear protective topcoat or sealant to maintain color vibrancy and structural stability.

Are these sheets safe for interior applications like furniture?

Absolutely. Coloured plywood sheets are widely used in interior furniture design, wall panels, and decorative partitions because they combine form and function effectively. However, when using them indoors—especially in spaces like bedrooms, schools, or healthcare facilities—it’s essential to ensure that the sheets comply with health and safety regulations.

Look for products that meet E0 or E1 formaldehyde emission standards, which indicate low or negligible release of harmful volatile organic compounds (VOCs). In addition, any finishing materials (like varnishes, adhesives, or laminates) applied on top of coloured plywood sheets should be non-toxic and eco-friendly. These precautions make them safe for daily use in interior environments while contributing to indoor air quality.

How should coloured plywood sheets be stored?

Proper storage of coloured plywood sheets is critical to preserving both their appearance and structural integrity. These sheets should be stored in a cool, dry, and shaded area, ideally indoors or under a moisture-proof canopy. Avoid stacking them vertically without any support, as this could lead to warping or bending over time. Horizontal stacking with uniform support is preferred.

It’s also important to protect coloured surfaces from direct sunlight, which can cause fading, and from moisture, which may lead to delamination or swelling. Covering the stack with a breathable protective sheet (not plastic wrap, which can trap moisture) is a smart way to prevent surface abrasion, dirt accumulation, and humidity damage.

Can I paint over coloured plywood sheets?

Yes, painting over coloured plywood sheets is possible, but it requires careful surface preparation to ensure good adhesion and a smooth finish. Since these sheets already have a pigmented or laminated surface, they may repel paint or cause peeling if the right steps are not followed.

Start by lightly sanding the surface using fine-grit sandpaper (around 220-grit) to create micro-texture. This helps the paint adhere better. Next, apply a high-quality primer that is compatible with non-porous or previously finished surfaces. Once the primer is fully cured, you can apply your chosen topcoat, whether it’s acrylic, latex, or oil-based paint.

Painting over coloured plywood sheets allows you to customize the look while still retaining the core structural benefits of the material.