Welcome to My Blog! 🌟

Before we dive into the content, let’s stay connected! Join me on my social media platforms where I share exclusive insights, engage with our amazing community, and post regular updates. Here’s how you can connect with me:

📘 Facebook: Follow Me on Facebook

Now, let’s embark on this journey together. I hope you find the content here insightful, engaging, and most importantly, valuable. Let’s explore, learn, and grow together! 🚀

Feel free to share your thoughts and feedback in the comments or on my social media—I’d love to hear from you! 😊

Table of Contents

Introduction

The year 2025 is shaping up to be a pivotal time in the interior design and construction industries. As homeowners, architects, and contractors continue seeking cost-effective, stylish, and durable materials, the pvc marble sheet remains a standout choice. Known for its affordability, easy installation, and luxurious appearance, this material has taken the market by storm in recent years. The upcoming trends are focusing not only on aesthetic appeal but also on sustainability, innovation, and versatility.

With advances in production technology and shifting consumer preferences, the pvc marble sheet is evolving beyond traditional boundaries. Whether it’s being used in high-rise residential units, hotel lobbies, or modular kitchens, its design possibilities are nearly limitless. In this article, we explore the top five trends expected to dominate the pvc marble sheet market in 2025.

Trend 1: Eco-Friendly PVC Marble Sheet Materials Gain Popularity

Environmental consciousness is no longer a niche consideration—it has become a central driver in material selection for both commercial and residential construction. In 2025, more designers, developers, and homeowners are prioritizing eco-friendliness in every element of interior finishing, and the pvc marble sheet industry is adapting accordingly.

Leading manufacturers are now producing pvc marble sheet products that incorporate sustainable materials such as recycled PVC, biodegradable fillers, and renewable additives. By reusing post-industrial and post-consumer PVC, producers are effectively reducing plastic waste that would otherwise end up in landfills or the ocean. Moreover, water-based adhesives and non-toxic coatings are now being adopted to minimize the release of volatile organic compounds (VOCs), which can harm indoor air quality.

This shift is not only environmentally beneficial but also opens new markets for pvc marble sheet applications. For instance, healthcare facilities, daycare centers, and LEED-certified green buildings are increasingly specifying eco-friendly materials that meet strict environmental standards. These eco-conscious pvc marble sheet options offer high durability, excellent water resistance, and luxurious aesthetics—making them a versatile and responsible choice.

Additionally, the growing demand for transparency and traceability in product sourcing has led manufacturers to provide Environmental Product Declarations (EPDs) and third-party certifications. These certifications assure buyers that the pvc marble sheet they are selecting is not only high-performance but also environmentally sound.

As consumer awareness continues to rise and global sustainability goals take center stage, the use of eco-friendly pvc marble sheet materials will likely become a norm rather than a trend.

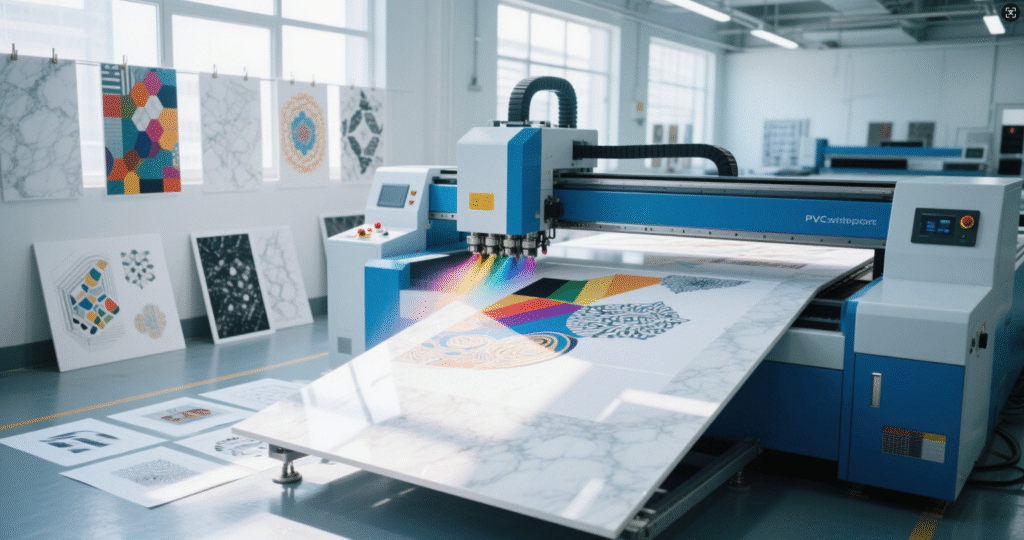

Trend 2: Digital Printing Enhances Customization of PVC Marble Sheet Designs

Personalization is a dominant trend in interior design, and digital printing technology is making it possible to create hyper-customized finishes that were once out of reach. In 2025, pvc marble sheet manufacturers are harnessing the power of advanced digital printing systems to produce more lifelike and diverse surface designs.

Unlike traditional printing methods that often result in repetitive or generic patterns, digital printing enables the creation of intricate marble textures with high-definition detail and color fidelity. Every vein, swirl, and gradient can be replicated with photographic accuracy. This means that a pvc marble sheet can now emulate rare stone looks such as Calacatta Gold, Nero Marquina, or Blue Bahia—without the cost, weight, or fragility of natural stone.

Digital printing also makes it easier to introduce customization for branding, theming, and interior harmony. Commercial spaces such as hotels, retail stores, and restaurants can order pvc marble sheet panels with proprietary designs, logos, or matching brand palettes. Residential users can choose from an expanded catalog of styles that better reflect their personal tastes or the architectural language of their homes.

This level of customization helps reduce waste as well. Because designs can be tailored to exact project specifications, there is less overproduction and fewer offcuts during installation. In addition, many digitally printed pvc marble sheet products are now UV-resistant and scratch-proof, preserving their vibrant appearance over time.

By allowing unique expressions and fine-tuned aesthetics, digital printing not only enhances the design flexibility of pvc marble sheet surfaces but also contributes to smarter, more efficient manufacturing.

Trend 3: Versatile Applications Extend Beyond Walls and Ceilings

Traditionally used as a decorative wall or ceiling cladding, the pvc marble sheet has evolved into a truly multifunctional material. In 2025, its application range has expanded well beyond vertical surfaces to include areas that were once dominated by heavier or more expensive materials.

Today’s pvc marble sheet products are commonly found in kitchen cabinetry, bathroom vanity facings, interior doors, display counters, and even custom furniture pieces. Thanks to advancements in core strength, scratch resistance, and water repellency, the material now supports medium-impact and semi-structural uses while maintaining its lightweight and easy-to-install benefits.

Homeowners and contractors alike appreciate the ease with which pvc marble sheet can be cut, shaped, and installed—often without the need for specialized tools. Many sheets come with pre-applied adhesive or interlocking systems, making them suitable for fast renovations with minimal downtime.

The material is particularly popular in urban housing and commercial fit-outs where time, space, and budget are critical considerations. For example, in small apartment renovations, pvc marble sheet panels are being used to refresh closet doors, sideboards, and even headboards. In hospitality settings, the same material is being applied to bar counters, elevator interiors, and signage backgrounds.

Furthermore, because pvc marble sheet is highly resistant to moisture, it performs well in humid environments such as saunas, spas, and restrooms. With the increasing need for hygienic, easy-to-clean surfaces, especially in public and semi-public areas, its antimicrobial finishes add another layer of functionality.

This growing list of use cases signals a new era for pvc marble sheet products—one where design innovation meets practicality across every corner of interior space.

Trend 4: Larger Sheet Sizes and Seamless Finishing Take Center Stage

Consumers are gravitating toward seamless aesthetics in 2025. To meet this demand, manufacturers are offering larger pvc marble sheet sizes that reduce the need for joints or seams. This creates a clean, uninterrupted look that enhances the perception of space and luxury.

Let’s take a look at a comparative table showing the evolution of pvc marble sheet sizing and aesthetics from 2020 to 2025.

| Year | Standard Size (mm) | Seam Visibility | Market Demand Focus | Typical Applications |

|---|---|---|---|---|

| 2020 | 1220 x 2440 | High | Budget and Quick Install | Walls, Ceilings |

| 2022 | 1220 x 2800 | Medium | Style and Efficiency | Feature Walls, Kitchens |

| 2023 | 1300 x 3000 | Low | Larger Surfaces | Commercial Interiors |

| 2024 | 1500 x 3050 | Very Low | Seamless Luxury | Hotel Lobbies, Showrooms |

| 2025 | 1600 x 3200+ | Minimal to None | Seamless, Custom Install | High-End Residences, Offices |

This move toward seamless finishing doesn’t just elevate aesthetics; it also simplifies maintenance. Without grout lines or joins, cleaning becomes quicker and mold or stain accumulation is minimized.

Trend 5: Hybrid and Textured Surfaces Provide Sensory Appeal

A major innovation in interior materials for 2025 is the shift toward surfaces that offer not just visual appeal but also tactile richness. While earlier designs prioritized sleek, glossy looks, today’s consumers are looking for experiences that engage multiple senses. This is where the latest pvc marble sheet trends truly shine—by incorporating hybrid and textured surfaces that deliver depth, warmth, and interactivity.

The trend includes a variety of new finishes and textures. Matte coatings are replacing high-gloss layers in many contemporary projects, offering a softer and more refined aesthetic. Matte surfaces help diffuse light more gently, reducing glare and enhancing the subtle details of marble veining. Many designers prefer this understated elegance for residential bedrooms, boutique hotel lobbies, and modern office spaces.

Another growing feature is 3D embossing. By adding physical texture to the surface of the pvc marble sheet, embossing creates a more lifelike feel that closely mimics the grain and structure of natural stone. These raised patterns can be felt under the fingertips, making them ideal for areas where both appearance and touch matter—like headboards, reception counters, and feature walls.

Pearl-like finishes and hybrid combinations such as matte-gloss contrasts or stone-metal fusions are also gaining traction. These complex finishes interact with ambient lighting in dynamic ways, shifting in tone and reflectivity depending on the viewer’s angle. This gives designers more tools to play with light, mood, and shadow in interior compositions.

From a sensory design standpoint, these advancements are part of a larger movement. People increasingly desire spaces that feel alive, comforting, and engaging—not sterile or uniform. A thoughtfully textured pvc marble sheet panel can add personality to a room, turning a simple partition into a design feature or a cabinet face into a conversation piece.

Additionally, these surfaces are not just about looks or touch—they are also functional. Many of the newer textures offer fingerprint resistance, better scratch protection, and anti-slip properties, particularly when used in flooring or high-contact surfaces.

The ability of the pvc marble sheet to integrate texture without sacrificing its core benefits—like being lightweight, moisture-resistant, and easy to install—makes it one of the most versatile and desirable materials for 2025 and beyond. As homeowners and architects continue to seek out multi-sensory environments, textured and hybrid surface trends will likely remain at the forefront of design innovation.

Conclusion

As we move into 2025, the pvc marble sheet is transforming from a practical building material to a design statement. With the integration of eco-conscious materials, advanced printing, versatile applications, seamless finishes, and textured surfaces, it is clear that this product is far more than a marble alternative.

Designers, architects, and homeowners are recognizing its potential for both functional and aesthetic transformations. The innovation in this field shows no signs of slowing down, and the pvc marble sheet continues to evolve in ways that are both exciting and sustainable.

Whether you’re revamping a home or constructing a commercial facility, staying on top of these trends ensures that your interiors are stylish, durable, and future-ready.

FAQ

What is a PVC marble sheet made of?

A pvc marble sheet is typically made from polyvinyl chloride (PVC) resin and calcium carbonate. It mimics the look of natural marble using printed decorative films and protective coatings. The core layers are designed to be water-resistant and durable.

Is a PVC marble sheet suitable for wet areas like bathrooms?

Yes, it is highly suitable for wet areas due to its water-resistant and non-porous nature. It is commonly used in bathrooms, kitchens, and even spa facilities. However, proper sealing around edges is essential to maintain its longevity.

How long does a PVC marble sheet last?

With proper installation and maintenance, a pvc marble sheet can last 10 to 20 years. Its resistance to moisture, stains, and scratches contributes to its extended lifespan in both residential and commercial environments.

Can I install PVC marble sheets myself?

Many homeowners opt for DIY installation due to the lightweight nature and adhesive backing of most pvc marble sheet variants. However, for larger or more complex projects, professional installation is recommended to achieve the best results.

Are there any limitations to using PVC marble sheets?

While highly versatile, pvc marble sheet materials can have some limitations. They may not perform well under extreme heat and should not be installed near open flames. Also, sharp objects can potentially damage the surface, so precautions are necessary in high-traffic or kitchen areas.