Selecting the right SPC flooring manufacturer can make or break your flooring project. From residential spaces to large commercial developments, the quality, durability, and aesthetic appeal of Stone Plastic Composite (SPC) flooring depend heavily on the manufacturer. In this blog, we dive deep into what makes a manufacturer reliable, cost-effective, and innovative in 2026 and beyond.

Table of Contents

Key Points You Will Learn in This Blog Post

- Why choosing the right SPC flooring manufacturers is critical for project success.

- Core criteria for evaluating quality, technology, and certifications.

- Comparison between domestic and international manufacturers.

- Insights into material selection, performance, and sustainability.

- Supply chain efficiency, customization, and after-sales support.

- Cost-benefit analysis: upfront cost vs total cost of ownership.

- Expert opinions and data-driven insights.

- Frequently Asked Questions to address buyer concerns.

Introduction

SPC flooring has rapidly grown in popularity due to its durability, water resistance, and eco-friendly properties. According to Allied Market Research (2024), the global SPC flooring market is expected to reach $25.8 billion by 2030, growing at a CAGR of 7.3%. This surge highlights the importance of partnering with manufacturers who can consistently deliver high-quality, innovative flooring solutions.

SPC flooring manufacturers are not just suppliers—they are technology partners. Their expertise determines product longevity, performance under extreme conditions, and compliance with international safety standards.

Understanding SPC Flooring Manufacturers

What Defines an SPC Flooring Manufacturer?

SPC flooring manufacturers specialize in producing Stone Plastic Composite flooring, combining limestone powder and PVC with innovative polymer layers. The manufacturer’s role includes:

- R&D for durable, water-resistant formulas.

- Precision production and quality control.

- Supply chain and logistics management for timely delivery.

Core Capabilities to Look For

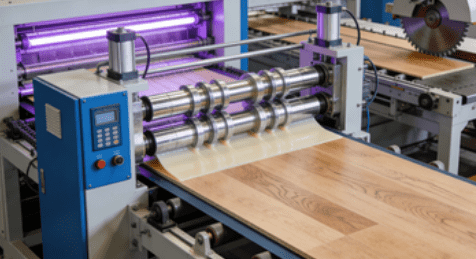

- Advanced extrusion, pressing, and lamination technologies.

- Automated cutting, edge finishing, and embossing systems.

- Consistent quality audits to comply with ISO, CE, FloorScore, and GREENGUARD standards.

Key Evaluation Criteria

1. Material Selection

High-performance SPC flooring relies on:

- Limestone purity: High-quality limestone ensures stable thickness and density.

- PVC quality: Determines flexibility, toughness, and surface finish.

- UV-resistant wear layers: Prevent fading over years of exposure.

Expert Insight: Dr. Emily Chen, Material Scientist at the Flooring Institute, notes, “The combination of high-purity limestone and optimized PVC ratios can increase lifespan by up to 30% compared to lower-grade materials.”

2. Production Technology

- Precision extrusion: Achieves uniform thickness and prevents warping.

- Automated embossing: Mimics real wood, stone, or tile patterns for aesthetic appeal.

- Edge finishing: Smooth, precise edges reduce installation issues.

3. Certifications & Compliance

A reliable SPC flooring manufacturer should have:

- ISO 9001: Quality management system certification.

- CE certification for European markets.

- FloorScore/GREENGUARD certification for indoor air quality compliance.

- REACH compliance for chemical safety standards.

Domestic vs International SPC Flooring Manufacturers

Domestic Manufacturers

Advantages:

- Lower shipping costs and faster lead times.

- Easier communication and project adjustments.

- Flexibility for small to medium-scale projects.

Disadvantages:

- Limited access to advanced production technologies.

- Fewer global certifications for export compliance.

International Manufacturers

Advantages:

- Cutting-edge production technology and high-end finishes.

- Recognized certifications for global markets.

- Advanced R&D leading to innovative SPC products.

Disadvantages:

- Higher shipping costs and longer lead times.

- Possible communication and cultural barriers.

Decision Tip

For large-scale, high-end projects, combining domestic cost-efficiency with international innovation often yields the best results.

Supply Chain Efficiency and Support

Integrated Supply Chain

Leading manufacturers, like Shandong Panel International Trade Co., Ltd., integrate:

- Logistics partnerships for rapid global delivery.

- Inventory management systems for accurate stock tracking.

- End-to-end solutions including material sourcing, production, and distribution.

Customization and Technical Support

- Tailored options: color, texture, thickness, packaging.

- Installation and maintenance guidance.

- Prompt after-sales support and warranty services.

Industry Note: According to Flooring Today Magazine, “Manufacturers who integrate R&D with supply chain solutions reduce project delays by 25-30% on average.”

Environmental and Sustainability Considerations

Material Efficiency

SPC flooring manufacturers minimize waste by:

- Precision molding and cutting processes.

- Recycling excess material back into production.

Recyclability and Eco-Friendliness

- Thermoplastic layers are often recyclable.

- Reduced lifecycle emissions compared to metal-reinforced or traditional laminate flooring.

Regulatory Compliance

Eco-conscious projects benefit from manufacturers adhering to:

- LEED construction guidelines.

- ISO 14001 environmental management standards.

Cost Analysis: Initial vs Total Value

Upfront Cost vs Long-Term ROI

- Plastic and composite materials in SPC flooring reduce maintenance and replacement costs.

- Longer lifespan and resistance to moisture minimize downtime and refurbishment needs.

Case Study

A commercial project in Shanghai replaced traditional laminate with SPC flooring from Shandong Panel International Trade Co., Ltd. The outcome:

- 35% reduction in maintenance costs over 5 years.

- Zero replacement due to water damage.

- Positive client feedback on durability and finish.

Performance Comparison of Manufacturers

| Feature | Domestic Manufacturer | International Manufacturer | Notes |

|---|---|---|---|

| Lead Time | 7–14 days | 21–30 days | Domestic faster for local projects |

| Certification | ISO, local | ISO, CE, FloorScore | International offers more global compliance |

| Price | Lower | Higher | Balance cost with quality |

| Innovation | Moderate | High | International may offer more R&D solutions |

| Customization | High | Medium | Domestic often more flexible |

Conclusion

Selecting the right SPC flooring manufacturer is a blend of evaluating materials, technology, certifications, supply chain efficiency, and customer support. High-quality manufacturers ensure:

- Durable, water-resistant, and visually appealing flooring.

- Eco-friendly and sustainable production.

- Timely delivery, customization, and after-sales service.

By balancing cost, innovation, and reliability, buyers can achieve superior results for residential, commercial, and industrial flooring projects. Partnering with professional manufacturers ensures both a beautiful finish and a long-term investment in quality.

Expert Tip: John Li, CEO of Shandong Panel International Trade Co., Ltd., states, “A manufacturer with strong R&D, global certification, and supply chain integration is not just a supplier—they are a project partner.”

FAQ

What makes an SPC flooring manufacturer reliable?

Look for quality materials, advanced production technology, certifications, customization, and robust supply chain management.

How do I check the manufacturer’s credibility?

Request samples, factory visits, references, and check international certifications such as ISO, CE, or FloorScore.

Can manufacturers produce eco-friendly SPC flooring?

Yes, many use recyclable thermoplastics and comply with LEED and GREENGUARD standards.

Should I choose a domestic or international manufacturer?

Domestic is cost-effective and faster; international offers high-end finishes and global compliance. Choose based on project scale and quality requirements.

What post-purchase support is typical?

Top manufacturers provide installation guidance, warranty, technical troubleshooting, and logistics support.

Let’s Keep in Touch!

Thanks for reading—I’m glad you joined me on this journey!

If you found this content valuable, insightful, or thought-provoking, I’d love to hear your thoughts.

📘 Follow me on Facebook for exclusive tips, behind-the-scenes insights, and community discussions.

👉 Click here to connect

Feel free to share your feedback or questions in the comments or on social media—I’m always here to chat.

Let’s keep exploring, learning, and growing—together!