Table of Contents

Introduction

Decor PVC panels are widely used in commercial and residential settings for their versatility, durability, and aesthetic appeal. However, prolonged exposure to sunlight and environmental elements can cause fading, discoloration, and a decline in overall visual quality. For B2B buyers, understanding strategies to prevent fading in decor PVC panels is critical to ensuring long-lasting installations and protecting investment value. In this article, we explore eight brilliant strategies to maintain the color and vibrancy of decor PVC panels over time.

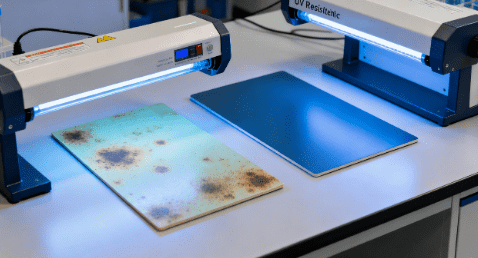

Strategy 1: Choose UV-Resistant Decor PVC Panels

Importance of UV Resistance

One of the most effective ways to prevent fading is to select panels specifically designed with UV-resistant additives. These materials reduce the degradation of color caused by prolonged exposure to sunlight.

How to Evaluate UV-Resistant Panels

When evaluating suppliers, check for UV stabilization certifications and lab-tested resistance ratings. Panels that meet these standards provide long-term color retention and durability.

Strategy 2: Use Protective Coatings on Decor PVC Panels

Clear Coatings for Color Longevity

Applying a protective clear coating on decor PVC panels can significantly reduce fading. Coatings provide a barrier against UV radiation, moisture, and pollutants.

Maintenance and Reapplication

Regular inspection and reapplication of coatings ensure continued effectiveness. For commercial installations, this maintenance routine can extend panel lifespan substantially.

Strategy 3: Optimize Installation Orientation and Placement

Minimizing Direct Sun Exposure

The direction and placement of decor PVC panels influence the degree of sunlight exposure. Installing panels in shaded areas or using architectural elements to block harsh sunlight can prevent premature fading.

Strategic Use of Shade Structures

Integrating awnings, overhangs, or other shade mechanisms in commercial or residential projects further reduces UV impact on decor PVC panels.

Strategy 4: Consider Panel Thickness and Surface Texture

Thickness Matters for Durability

Thicker decor PVC panels are less prone to warping and color loss. For high-traffic or outdoor areas, selecting panels with sufficient thickness ensures both structural integrity and visual stability.

Surface Texture and Finish

The finish of the panel, whether matte or glossy, can influence how sunlight affects color. Choosing the right texture helps minimize reflection and fading over time.

Strategy 5: Maintain Panels with Proper Cleaning and Care

Routine Cleaning Practices

Regular cleaning removes dirt, dust, and environmental contaminants that can accelerate fading. Use mild, non-abrasive cleaning agents suitable for decor PVC panels.

Preventing Damage During Maintenance

Avoid harsh chemicals or abrasive tools, as they can strip protective coatings and compromise UV resistance. Scheduled maintenance protocols are essential for long-term performance.

Strategy 6: Select High-Quality Pigments and Additives

Role of Colorants in Fading Prevention

The choice of pigments and additives directly affects how decor PVC panels respond to sunlight. High-quality, fade-resistant pigments retain vibrancy over extended periods.

Supplier Evaluation and Testing

B2B buyers should request product datasheets and independent testing reports to verify the UV stability of decor PVC panels before bulk purchase.

Strategy 7: Environmental Considerations and Site-Specific Planning

Assessing Local Conditions

Factors such as humidity, temperature fluctuations, and pollution levels impact fading rates. Selecting panels suited to local environmental conditions enhances longevity.

Combining Strategies for Optimal Performance

Using UV-resistant panels, protective coatings, and strategic placement together ensures maximum color retention and reduces maintenance costs.

Strategy 8: Monitor and Replace Panels Proactively

Scheduled Inspections

Regular inspection schedules help identify panels showing early signs of fading. Timely action prevents deterioration from affecting the overall visual quality of the installation.

Cost-Benefit Analysis of Replacement

While replacing panels may involve upfront costs, maintaining the aesthetic appeal and brand image of commercial spaces justifies proactive replacement strategies.

Comparison Table: Key Factors for Preventing Fading in Decor PVC Panels

| Strategy | Benefits | Considerations | Best Use Case |

|---|---|---|---|

| UV-Resistant Panels | Long-term color retention, durability | Higher initial cost | Outdoor installations, sunny climates |

| Protective Coatings | Barrier against UV, moisture, pollution | Requires maintenance | High-traffic commercial spaces |

| Optimal Placement | Minimizes direct sun exposure | May limit design options | Exterior walls, facades |

| Thickness & Surface Texture | Structural integrity, reduced fading | Heavier panels | Roof or wall panels exposed to sunlight |

| Proper Cleaning & Maintenance | Removes damaging contaminants | Regular labor required | All commercial and residential projects |

| High-Quality Pigments | Vibrant colors over time | Higher material cost | Premium interior or exterior projects |

| Environmental Planning | Tailored performance | Site analysis needed | Regions with extreme weather or pollution |

| Proactive Replacement | Maintains aesthetics | Replacement costs | Brand-sensitive commercial facilities |

Conclusion

Preventing fading in decor PVC panels requires a combination of material selection, protective measures, strategic planning, and proactive maintenance. By implementing these eight strategies, B2B buyers can ensure long-lasting installations that maintain color vibrancy, reduce maintenance costs, and enhance the aesthetic and commercial value of their projects. Prioritizing UV resistance, proper care, and smart planning is essential for any organization investing in decor PVC panels.

FAQ

How can I identify UV-resistant decor PVC panels?

Look for panels with UV stabilization certifications, lab-tested resistance ratings, and supplier-provided datasheets confirming long-term color retention.

How often should protective coatings be reapplied?

Reapplication depends on exposure and environmental conditions, typically every 2–3 years for outdoor installations.

Do matte and glossy finishes affect fading differently?

Yes, matte finishes reduce reflection and may fade more evenly, while glossy finishes can show surface imperfections and require careful maintenance.

Is thicker PVC always better for preventing fading?

Thicker panels offer better structural stability and may help with color retention, especially in outdoor or high-traffic environments.

Can site planning alone prevent fading?

Site planning helps reduce direct sunlight exposure but should be combined with UV-resistant materials and protective coatings for optimal results.

Let’s Keep in Touch! 🌟

Thanks for reading—I’m glad you joined me on this journey!

If you found this content valuable, insightful, or thought-provoking, I’d love to hear your thoughts.

📘 Follow me on Facebook for exclusive tips, behind-the-scenes insights, and community discussions.

👉 Click here to connect

Feel free to share your feedback or questions in the comments or on social media—I’m always here to chat.

Let’s keep exploring, learning, and growing—together! 🚀😊