Table of Contents

Introduction

WPC, or Wood Plastic Composite, has become a popular material in construction, interior design, and outdoor applications due to its durability, versatility, and eco-friendly properties. Understanding the WPC meaning is essential for industrial buyers, architects, and builders who aim to select the right materials for their projects. This guide explores five essential facts about WPC, including its composition, applications, advantages, environmental impact, and market trends.

Understanding WPC Meaning and Composition

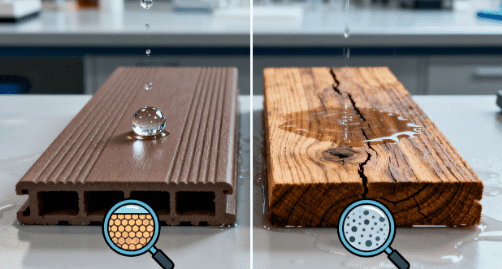

WPC is a composite material made by combining wood fibers or sawdust with thermoplastics such as polyethylene, polypropylene, or PVC. The WPC meaning extends beyond its basic definition to include the performance benefits achieved by this combination. The wood fibers provide strength and aesthetic appeal, while the plastic component adds durability, moisture resistance, and low maintenance requirements.

Key Components of WPC

- Wood fibers: Provide natural texture, appearance, and strength.

- Plastic resins: Improve moisture resistance, flexibility, and longevity.

- Additives: Stabilizers, colorants, and UV inhibitors enhance performance and appearance.

Advantages of WPC Over Traditional Wood

WPC materials offer several advantages over solid wood, including higher resistance to rot and insect damage, lower maintenance requirements, and the ability to mold into various shapes and colors. These properties make it an ideal choice for both indoor and outdoor applications.

Applications of WPC

Indoor Applications

WPC is widely used for wall panels, flooring, ceiling panels, and decorative features. Its versatility allows designers to create aesthetically pleasing interiors with materials that are durable and easy to maintain.

Outdoor Applications

For outdoor environments, WPC is commonly used in decking, fencing, pergolas, and garden furniture. Its resistance to moisture, UV rays, and temperature fluctuations ensures long-lasting performance.

Table: Typical WPC Applications and Benefits

| Application | Typical Use | Key Benefits | Notes |

|---|---|---|---|

| Wall panels | Offices, homes, hospitals | Aesthetic appeal, easy maintenance | Can be customized with textures and colors |

| Flooring | Commercial and residential | Durable, slip-resistant, water-resistant | Suitable for high-traffic areas |

| Decking | Outdoor spaces | Weather-resistant, rot-proof | UV and moisture resistant |

| Fencing | Gardens, parks | Long-lasting, low maintenance | Available in multiple colors and finishes |

| Furniture | Benches, tables, chairs | Lightweight, durable | Can be molded into various shapes |

Environmental Impact and Sustainability

WPC is considered an environmentally friendly material because it often incorporates recycled wood and plastic, reducing the demand for virgin materials. The manufacturing process of WPC also produces fewer emissions compared to traditional wood processing. Additionally, WPC is fully recyclable, contributing to a circular economy.

Benefits of Using WPC for Sustainable Construction

- Recycled content: Reduces waste and promotes recycling.

- Long lifespan: Minimizes replacement and resource consumption.

- Low maintenance: Reduces chemical treatments needed for wood.

Market Trends and Industry Insights

The global WPC market has been growing steadily due to rising demand in construction, furniture, and interior design sectors. B2B buyers are increasingly considering WPC for its durability, low maintenance, and aesthetic versatility. Regional trends indicate higher adoption rates in North America, Europe, and Asia-Pacific, particularly in outdoor decking and architectural applications.

Choosing the Right WPC Supplier

Selecting a reliable WPC supplier involves evaluating product quality, production capacity, certifications, and after-sales support. Ensuring that the supplier adheres to international standards such as ISO can help mitigate risks and ensure consistent material quality.

Challenges in Using WPC

Despite its advantages, WPC presents certain challenges. It may be prone to scratching, thermal expansion, and color fading over time. Proper installation, protective coatings, and regular maintenance can mitigate these issues. Industrial buyers should be aware of these factors when specifying materials for projects.

Installation and Maintenance Tips

- Use recommended fasteners and adhesives.

- Allow for thermal expansion during installation.

- Apply UV-protective coatings for outdoor use.

- Follow manufacturer guidelines for cleaning and maintenance.

Conclusion

Understanding the WPC meaning and its applications is critical for B2B buyers, architects, and construction professionals seeking durable, versatile, and sustainable materials. WPC offers advantages in indoor and outdoor environments, including low maintenance, resistance to moisture and insects, and aesthetic flexibility. By considering environmental impact, supplier reliability, and proper installation, buyers can maximize the benefits of WPC in their projects.

FAQ

What is the full meaning of WPC?

WPC stands for Wood Plastic Composite, a material combining wood fibers with thermoplastics to create a durable and versatile composite suitable for various applications.

What are the main uses of WPC?

WPC is used in indoor and outdoor applications, including wall panels, flooring, decking, fencing, and furniture. It offers durability, low maintenance, and aesthetic flexibility.

How does WPC compare to traditional wood?

WPC is more resistant to moisture, insects, and rot compared to solid wood. It requires less maintenance and can be molded into different shapes and colors, offering greater versatility.

Is WPC environmentally friendly?

Yes, WPC often contains recycled wood and plastic, reducing the need for virgin materials. It is recyclable and contributes to sustainable construction practices.

What should B2B buyers consider when selecting WPC?

Buyers should evaluate product quality, supplier certifications, manufacturing processes, installation requirements, and long-term performance to ensure the material meets project needs.

How should WPC be maintained?

Regular cleaning with mild detergents, applying UV protection for outdoor use, and monitoring for scratches or thermal expansion are recommended to extend the lifespan of WPC products.

Let’s Keep in Touch! 🌟

Thanks for reading—I’m glad you joined me on this journey!

If you found this content valuable, insightful, or thought-provoking, I’d love to hear your thoughts.

📘 Follow me on Facebook for exclusive tips, behind-the-scenes insights, and community discussions.

👉 Click here to connect

Feel free to share your feedback or questions in the comments or on social media—I’m always here to chat.

Let’s keep exploring, learning, and growing—together! 🚀😊