Table of Contents

Introduction

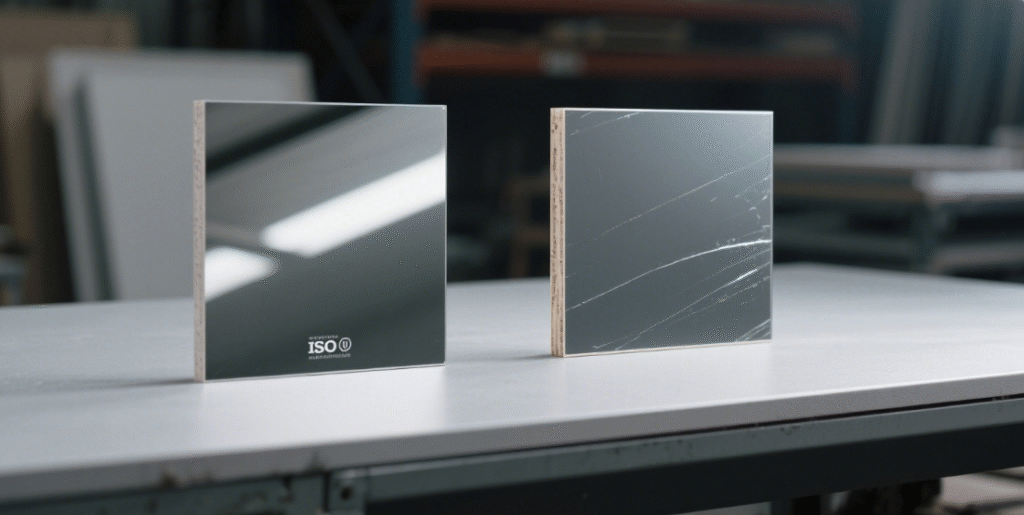

In the competitive world of custom board manufacturing, businesses strive to meet customer demands for high-quality products that are both durable and cost-effective. For companies like Shandong Panel International Trade Co., Ltd., which specializes in providing high-quality decorative materials, ISO certification is not just a regulatory requirement—it’s a competitive advantage. Whether it’s polyester acoustic panels, WPC boards, film-faced plywood, or UV panels, adhering to ISO Standards ensures that these custom boards meet the highest levels of quality and performance.

As industries around the world increasingly focus on sustainable and high-performance products, ISO certification serves as a standard that aligns product quality with international expectations. In this blog, we will explore why ISO certification is crucial for the custom board manufacturing industry, its impact on product quality, and how it benefits both manufacturers and end consumers.

What is ISO Certification and Why Does It Matter in Custom Board Manufacturing?

ISO certification refers to the adherence to international standards established by the International Organization for Standardization. These standards are designed to ensure products and services are safe, reliable, and of the highest quality. For custom board manufacturers, ISO certification is essential for proving their commitment to producing high-quality, consistent, and sustainable products.

What Does ISO Certification Mean for Custom Board Producers?

For manufacturers like Shandong Panel International Trade Co., Ltd., ISO certification means that their production processes, materials, and finished products meet stringent quality standards. This certification applies not just to the physical properties of the products (such as strength and durability), but also to the ethical and environmental standards they uphold.

ISO Standards ensure:

- Product Consistency: Custom boards like UV panels and commercial plywood must consistently meet quality requirements, which is facilitated by ISO guidelines.

- Compliance with Global Standards: ISO-certified companies can confidently compete in the global market, knowing their products meet international quality standards.

- Environmental Responsibility: Many ISO certifications, such as ISO 14001, are designed to encourage sustainable and environmentally friendly manufacturing processes.

ISO Certification and the Custom Board Production Process

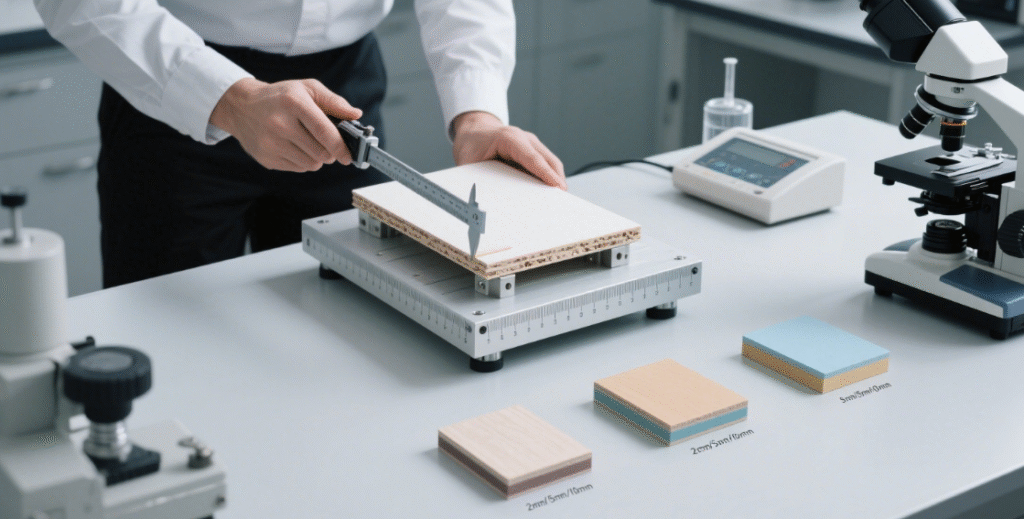

The process of obtaining ISO certification for custom board manufacturing involves adhering to specific standards and procedures. These standards are crucial in ensuring that each product, whether it’s soundproof boards, WPC panels, or film-faced plywood, meets both industry and environmental expectations.

Key ISO Certifications Relevant to Custom Board Manufacturing

| ISO Standard | Relevance to Custom Board Manufacturing |

|---|---|

| ISO 9001: Quality Management | Ensures that the manufacturer consistently produces high-quality products and improves its processes. |

| ISO 14001: Environmental Management | Focuses on reducing the environmental impact of the manufacturing process, which is vital for sustainable product lines like WPC panels. |

| ISO 45001: Occupational Health and Safety | Ensures that manufacturers prioritize safe working environments, reducing accidents during the production of custom boards. |

| ISO 50001: Energy Management | Helps manufacturers improve energy efficiency, which can lower production costs for products like acoustic panels. |

| ISO 50002: Energy Audits | Helps companies analyze energy use during production and implement improvements, ensuring that energy-intensive processes for boards are optimized. |

How ISO Certification Enhances the Quality of Custom Boards

1. Improved Product Reliability and Consistency

ISO-certified manufacturers follow strict guidelines that ensure their products meet consistent quality standards. Whether it’s UV boards that require high gloss finishes or commercial plywood that needs to be strong yet lightweight, ISO certification ensures that the boards meet the same performance standards each time.

2. Enhanced Customer Confidence

For businesses purchasing custom boards like soundproof panels or WPC boards, ISO certification acts as a sign of reliability and high quality. Customers are more likely to trust a manufacturer with proven adherence to international standards, knowing that the products they receive will meet the specifications and quality they expect.

3. Compliance with Industry Regulations

Many industries require ISO-certified products as part of their procurement process. For example, the construction industry often mandates that materials like film-faced plywood be sourced from certified suppliers to ensure safety and durability. By meeting ISO requirements, manufacturers can access a broader market and participate in larger-scale projects.

The Impact of ISO Certification on Custom Board Manufacturers and Customers

1. Streamlined Production and Reduced Costs

ISO-certified companies benefit from streamlined production processes due to well-established quality control systems. These systems not only ensure that products are consistently high quality but also help reduce waste and inefficiency, leading to cost savings. For example, by ensuring that each batch of WPC boards is of uniform quality, production time is optimized, and raw material use is minimized.

2. Increased Market Opportunities

With ISO certification, custom board manufacturers can expand their business beyond local markets to global customers. As international trade demands high-quality and certified products, having ISO certification becomes an essential tool for gaining entry into new markets. Manufacturers who meet ISO 9001 or ISO 14001 are recognized for their commitment to excellence, opening doors to partnerships and high-value contracts.

3. Continuous Improvement and Innovation

ISO certification encourages a culture of continuous improvement. This means manufacturers are always looking for ways to improve product performance, reduce costs, and innovate. At Shandong Panel International Trade Co., Ltd., this mindset drives our commitment to product innovation, whether it’s enhancing the acoustical properties of polyester acoustic panels or improving the aesthetic appeal of UV panels.

How ISO Certification Reduces Risks in Custom Board Manufacturing

1. Mitigating the Risk of Non-Compliance

In industries like construction or automotive, failing to meet quality standards can result in significant legal and financial consequences. By adhering to ISO Standards, manufacturers ensure that they comply with all relevant regulations, mitigating the risk of costly fines or product recalls.

2. Preventing Product Failures and Recalls

ISO-certified manufacturers perform rigorous quality control tests throughout the production process. This reduces the risk of product failures that could lead to recalls or safety hazards. For example, soundproof boards used in sensitive environments must meet strict durability and performance criteria. ISO certification ensures these boards can withstand wear and tear over time without compromising their functionality.

Conclusion

ISO certification is more than just a badge of quality; it’s a fundamental part of the modern custom board production process. From plywood to PVC boards to UV panels, manufacturers who adhere to ISO standards can consistently produce high-quality products, meet customer expectations, and enter global markets with confidence.

At Shandong Panel International Trade Co., Ltd., we are committed to providing high-quality custom boards that adhere to the highest ISO standards. Our team works tirelessly to ensure that each product, from polyester acoustic panels to film-faced plywood, is produced with precision, reliability, and environmental responsibility. Contact us today for more information about our ISO-certified products and to receive a tailored quote for your needs.

FAQ

What is ISO Certification for Custom Boards?

ISO certification for custom boards refers to a formal recognition that a company meets international standards for quality, safety, and environmental management. For manufacturers of plywood, PVC boards, UV panels, and soundproof boards, ISO certification demonstrates a commitment to consistent product quality, compliance with industry standards, and sustainable manufacturing practices. This certification is essential for gaining trust in both local and international markets.

How Does ISO Certification Benefit Custom Board Manufacturers?

ISO certification offers numerous benefits to custom board manufacturers, including:

- Consistent product quality: Standardized processes help ensure uniform quality in plywood, PVC boards, and other custom boards.

- Operational efficiency: Streamlined processes reduce waste and optimize production time.

- Market expansion: ISO certification opens doors to global markets that require certified products.

- Increased customer trust: Customers prefer buying from ISO-certified manufacturers, knowing they are getting reliable, high-quality products.

What Are the Key ISO Standards for Custom Board Production?

There are several key ISO standards relevant to custom board production, including:

- ISO 9001: This standard ensures a focus on quality management systems, enhancing consistency and efficiency in the production of custom boards.

- ISO 14001: Focuses on environmental management, helping companies minimize their environmental impact during production.

- ISO 45001: Addresses occupational health and safety, ensuring safe working conditions in the manufacturing process.

How Can ISO Certification Improve the Quality of Custom Boards?

ISO certification enhances the quality of custom boards by enforcing strict production protocols. By adhering to ISO standards, manufacturers can achieve:

- Consistency in product quality: Each board, whether PVC, plywood, or soundproof boards, meets defined quality benchmarks.

- Improved performance: Products undergo rigorous testing to ensure they perform well under different conditions.

- Reduced defects: Quality control processes identify and eliminate errors, reducing waste and increasing the overall lifespan of the products.

5. What Is the Process for Achieving ISO Certification in Custom Board Manufacturing?

Achieving ISO certification for custom boards involves the following steps:

- Initial assessment: Evaluate current manufacturing processes and identify gaps in meeting ISO standards.

- Implementation: Align production systems with ISO standards for quality, environmental, and safety management.

- Internal audit: Conduct an internal review to ensure processes are ISO-compliant.

- Certification audit: An external auditor will assess the system. If compliant, the company is awarded certification.

- Ongoing monitoring: Regular audits and continuous improvement are needed to maintain ISO status.

By following these steps, manufacturers ensure that their custom boards are produced with consistent quality and meet global standards.

Let’s Keep in Touch! 🌟

Thanks for reading—I’m glad you joined me on this journey!

If you found this content valuable, insightful, or thought-provoking, I’d love to hear your thoughts.

📘 Follow me on Facebook for exclusive tips, behind-the-scenes insights, and community discussions.

👉 Click here to connect

Feel free to share your feedback or questions in the comments or on social media—I’m always here to chat.

Let’s keep exploring, learning, and growing—together! 🚀😊