Welcome to My Blog! 🌟

Before we dive into the content, let’s stay connected! Join me on my social media platforms where I share exclusive insights, engage with our amazing community, and post regular updates. Here’s how you can connect with me:

📘 Facebook: Follow Me on Facebook

Now, let’s embark on this journey together. I hope you find the content here insightful, engaging, and most importantly, valuable. Let’s explore, learn, and grow together! 🚀

Feel free to share your thoughts and feedback in the comments or on my social media—I’d love to hear from you! 😊

Table of Contents

Introduction

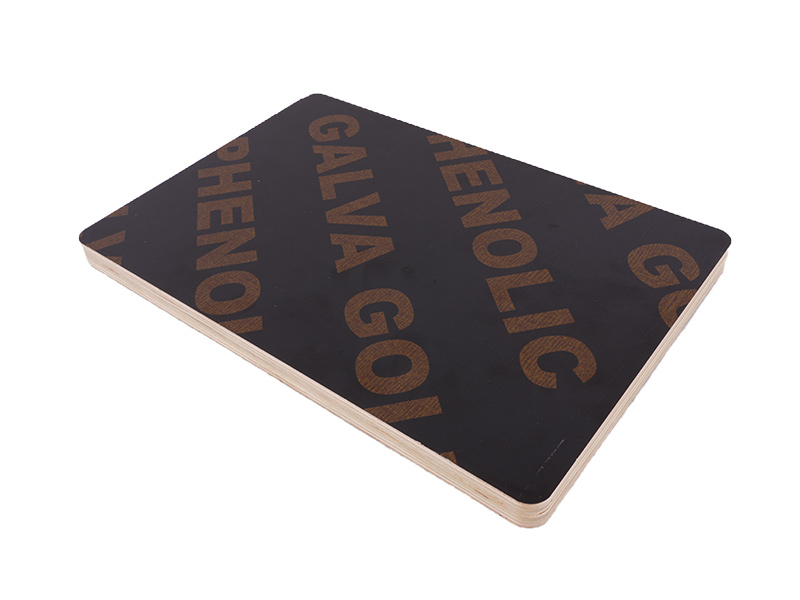

Is black plywood a bad idea? Many sellers and buyers alike may be hesitant about choosing black plywood due to misconceptions around its quality, performance, or cost-efficiency. But the truth is, black plywood—particularly film faced variants—offers outstanding benefits that make it a smart choice for construction professionals and materials resellers.

This article is designed to guide sellers and procurement professionals through five key truths about black plywood. We’ll demonstrate why it’s far from a “bad idea,” especially when used in applications like concrete formwork, industrial flooring, and other demanding environments.

Truth 1: Black Plywood Offers High Water Resistance and Durability

Contrary to common misconceptions, the appeal of these dark film-faced panels goes beyond mere aesthetics. Most varieties, especially those with phenolic resin coatings, are specifically engineered to withstand demanding outdoor environments. The protective black film layer acts as a robust barrier against water infiltration and harsh chemicals, making it highly suitable for frequent exposure to moisture.

Key Benefits:

- Ideal choice for concrete formwork applications where repeated contact with water occurs

- Effectively minimizes risks of delamination and swelling at the edges

- Can be reused multiple times across various construction cycles without significant degradation

These characteristics make such plywood alternatives invaluable to suppliers aiming to serve commercial construction and large-scale infrastructure projects.

Truth 2: Black Plywood Is Built for Strength and Reusability

One of the standout advantages of this product line is its exceptional structural integrity. Constructed using high-density hardwood, combi, or poplar cores, and bonded with waterproof adhesives, these panels maintain rigidity and resist warping even after extensive use. This stability contributes to enhanced load-bearing capabilities, whether applied horizontally as flooring or vertically as formwork.

Use Case Examples:

- Formwork for bridges, tunnels, and other heavy infrastructure

- Foundations and vertical support columns

- Slabs in high-rise buildings requiring precise mold stability

For distributors and vendors, this product should be marketed as a durable, reusable solution that maximizes the lifecycle value for contractors and end-users alike.

Truth 3: Black Plywood Meets Global Quality Standards

These coated plywood panels are far from low-grade materials. Established manufacturers produce them to meet and often exceed global standards such as ISO 9001, CE certification, and CARB emission regulations. Rigorous quality control protocols ensure consistent thickness, core bonding integrity, and smooth surface finishes, providing reliable performance in demanding industrial environments.

| Feature | Black Plywood (Film Faced) | Ordinary Plywood |

|---|---|---|

| Surface Finish | Phenolic black film-coated | Raw wood veneer |

| Water Resistance | High (phenolic resin layer) | Low to moderate |

| Reusability in Formwork | 10+ times (with proper care) | 1–3 times |

| Core Material | Poplar/Combi/Hardwood/Birch | Often softwood or mixed grades |

| Adhesive Type | Waterproof (WBP/MR/Melamine) | Usually interior-grade glue |

| Ideal Application | Concrete formwork, outdoor structures | Furniture, indoor panels |

This table showcases how this plywood stands apart in both quality and functionality.

Truth 4: Black Plywood Is Cost-Effective in the Long Run

Though these specialized panels may carry a slightly higher upfront cost compared to conventional boards, their overall economic benefit is significant. Promoting them can help buyers understand how investing in more durable materials leads to long-term savings by reducing the frequency of replacements, lowering labor costs, and improving the finished concrete surface quality.

Why It Saves Money:

- Reduced need for frequent panel replacement thanks to enhanced durability

- Cleaner concrete finishes minimize additional surface repairs or touch-ups

- Less warping results in quicker, more efficient work cycles

These benefits combine to generate tangible cost reductions, especially when used across multiple construction projects.

Truth 5: Black Plywood Is Ideal for Sellers Targeting Infrastructure and Commercial Projects

If your clientele includes construction contractors, real estate developers, or public infrastructure teams, For suppliers whose customers include contractors, property developers, or public infrastructure authorities, these film-faced, coated plywood panels are essential inventory. They satisfy stringent technical, environmental, and durability requirements demanded by large-scale projects.

For instance, manufacturers based in Shandong offer:

- Film-faced boards with durable phenolic coatings

- Multiple core options including poplar, combi, and birch

- Various thicknesses ranging from 9mm to 21mm

- Standard sizes such as 1220x2440mm and 1250x2550mm

- OEM/ODM services for customized branding and specifications

Given their widespread use in tunnels, bridge decks, support columns, and slab molds, these products present sellers with lucrative opportunities to cater to demanding construction sectors.

Conclusion

The notion that black plywood is a poor investment doesn’t hold up to scrutiny. For sellers looking to offer a high-performance, versatile, and widely accepted material, black plywood—especially film faced variants—presents an excellent business opportunity.

From superior durability and water resistance to broad industrial applications and cost-effectiveness, it is clearly a strong choice for demanding customers.

If you’re a reseller, supplier, or wholesaler, integrating high-grade black plywood into your offerings can elevate your product line and meet the evolving needs of modern construction professionals.

FAQ

What is black plywood used for?

This type of plywood is predominantly utilized in concrete formwork, industrial flooring, and various exterior applications such as scaffolding or structural panels. Its distinctive dark film coating—often made from phenolic or melamine resin—provides excellent water resistance and durability, allowing it to endure the harsh conditions commonly found on construction sites. Because of these protective properties, it is highly favored for large infrastructure projects, high-rise building construction, and even certain outdoor furniture designs that require resilience against moisture and wear.

Is black plywood reusable?

Yes, black plywood—especially film faced plywood—is highly reusable. In formwork applications, it can typically be reused over 10 times if properly handled and maintained. Contractors appreciate its long life cycle and clean removal from concrete surfaces. Regular cleaning and sealing of edges can significantly extend its usability, making it a cost-effective material for repetitive construction tasks.

Does black plywood meet quality standards?

High-grade versions of this coated plywood conform to multiple international quality and safety standards, including ISO 9001, CE marking, and CARB emissions regulations. Top manufacturers implement rigorous inspection protocols to verify bonding strength, moisture resistance, and dimensional accuracy. Additionally, many products undergo third-party certification processes that assess formaldehyde emissions and environmental compliance. Selecting certified panels ensures reliable performance and regulatory compliance on demanding construction sites, giving buyers confidence in product safety and quality.

How does black plywood compare to MDF?

Compared to MDF (Medium-Density Fiberboard), black plywood offers superior strength, better water resistance, and higher load-bearing capability. It is more suitable for structural and outdoor applications, while MDF is preferred for indoor uses such as cabinetry, shelving, and decorative panels. Unlike MDF, black plywood maintains integrity in humid or wet environments and can handle mechanical stress without warping or breaking easily.

Why should sellers promote black plywood?

Suppliers have compelling reasons to highlight this durable film-faced plywood in their product lines, given its strong market demand across industrial and commercial construction sectors. It offers excellent resale value, encourages repeat purchases, and generates high customer satisfaction due to its reliability and versatility. Furthermore, it appeals strongly to procurement professionals involved in government and infrastructure contracts, which often require materials that are compliant with stringent technical and environmental standards. Actively promoting such products can bolster supplier reputation and facilitate long-term business relationships with major construction clients.