Welcome to My Blog! 🌟

Before we dive into the content, let’s stay connected! Join me on my social media platforms where I share exclusive insights, engage with our amazing community, and post regular updates. Here’s how you can connect with me:

📘 Facebook: Follow Me on Facebook

Now, let’s embark on this journey together. I hope you find the content here insightful, engaging, and most importantly, valuable. Let’s explore, learn, and grow together! 🚀

Feel free to share your thoughts and feedback in the comments or on my social media—I’d love to hear from you! 😊

Table of Contents

Introduction

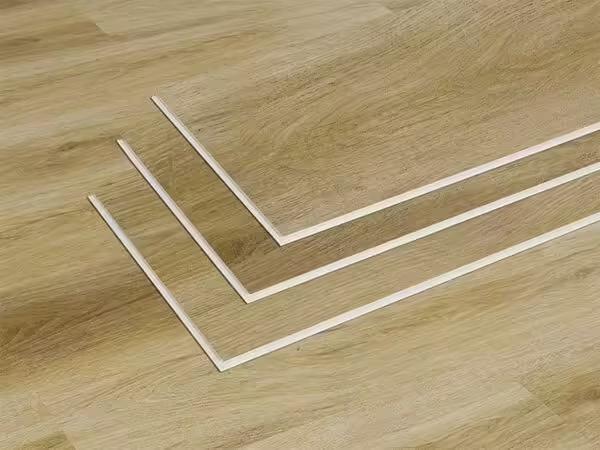

SPC vinyl flooring, also known as stone plastic composite flooring, has surged in popularity due to its durability, waterproof nature, and aesthetic appeal. It’s a practical choice for both residential and commercial spaces. However, while installing SPC vinyl flooring may seem straightforward, there are common pitfalls that can compromise the performance and longevity of the floor. In this blog post, we’ll explore the seven worst mistakes made during installation and how to avoid them to ensure your investment in SPC vinyl flooring pays off.

Mistake 1: Failing to Acclimate SPC Vinyl Flooring

One of the most frequent mistakes during SPC vinyl flooring installation is neglecting the acclimation process. While it’s true that SPC vinyl flooring is more dimensionally stable than other types of vinyl flooring, it is not entirely immune to environmental changes. Fluctuations in temperature and humidity can cause slight expansion or contraction, especially if the product is stored or installed in a climate drastically different from its final environment.

Skipping acclimation can result in a range of problems post-installation. Homeowners often discover gapping between planks or buckling, where the floor rises unevenly. These issues can compromise the appearance and functionality of the flooring and may necessitate costly repairs or a complete redo of the installation.

Why It Matters:

Acclimation allows the SPC vinyl flooring to adapt to the room’s ambient temperature and humidity. This adjustment helps stabilize the material, making it less likely to shift after installation. The room environment should be similar to normal living conditions, especially if heating or cooling systems are not yet operational during construction.

How to Avoid:

- Bring the unopened flooring boxes into the room where the installation will take place.

- Let the flooring acclimate for at least 48 hours before installation begins.

- Stack the boxes flat and ensure air circulation around them.

- Maintain the room’s temperature between 65°F and 85°F with a relative humidity of 35% to 65%.

Taking this extra step may seem like a delay, but it’s a small price to pay for long-lasting results.

Mistake 2: Ignoring Subfloor Preparation for SPC Vinyl Flooring

SPC vinyl flooring is known for its rigidity and strength, but even the best flooring can fail if installed over a poorly prepared subfloor. A common yet critical error is assuming the subfloor doesn’t require attention. An uneven, dusty, or damp subfloor can lead to serious installation problems.

When the subfloor is uneven, some areas may not fully support the flooring. This causes the planks to flex, creating an annoying clicking sound or even cracking the interlocking mechanisms over time. Dirty or moist subfloors can lead to mold growth, unpleasant odors, or adhesion issues.

Why It Matters:

A clean, dry, and level subfloor is essential for a seamless finish and long-term durability. If your subfloor is unstable or compromised, the integrity of your SPC vinyl flooring is at risk.

How to Avoid:

- Clean Thoroughly: Vacuum and mop the surface to eliminate dust, debris, or oils.

- Check for Moisture: Use a moisture meter, especially if installing over concrete. The moisture level should not exceed the flooring manufacturer’s recommendations.

- Inspect for Flatness: Use a long level or straight edge. No high or low points should exceed 3/16 inch over a 10-foot span.

- Correct Imperfections: Use leveling compounds to fill dips or grind down high spots.

Neglecting subfloor preparation can quickly turn a great product into a costly mistake. Always inspect and fix the subfloor before moving forward.

Mistake 3: Not Leaving Proper Expansion Gaps

Another widespread mistake involves improper expansion gap allowances. It’s easy to assume that because SPC vinyl flooring is rigid and engineered to resist movement, you can install it tightly against the wall. However, that assumption could be a costly one.

As room temperatures change and relative humidity fluctuates, even rigid-core flooring materials like SPC can undergo minor expansion and contraction. Without a proper expansion gap, the flooring has no room to move. This pressure builds over time and can force planks to push against one another or the wall, resulting in warping or lifting at the edges.

Why It Matters:

The expansion gap is not a flaw in installation—it’s a crucial feature that allows the flooring to adapt naturally to its environment. Skipping this can lead to buckling, creaking noises, and a shortened lifespan of your flooring.

How to Avoid:

- Plan Expansion Gaps in Advance: Before you start, mark a 1/4 inch space along all walls and fixed objects.

- Use Spacers: Installers often forget or discard spacers midway through the process. Use them consistently around all perimeters.

- Leave Room Around Pipes and Columns: It’s not just about wall edges. Any fixed element that interrupts the floor needs clearance.

- Cover the Gaps: After installation, use baseboards or molding to cover these gaps, giving the floor a clean finish without impeding its ability to move.

Overlooking this simple but critical detail can ruin what would otherwise be a flawless installation. Expansion gaps are not just a best practice—they’re a requirement for any floating floor, including SPC vinyl flooring.

Mistake 4: Using the Wrong Tools for SPC Vinyl Flooring

Some DIY installers attempt to use tools not intended for SPC vinyl flooring, which often leads to inaccurate cuts or damage to the planks. Using improper tools can also affect the locking mechanism, leading to loose joints and water infiltration.

Recommended Tools for SPC Vinyl Flooring:

| Tool | Purpose |

|---|---|

| Utility Knife | Cutting planks |

| Rubber Mallet | Securing planks without damage |

| Tapping Block | Locking planks together |

| Spacers | Ensuring expansion gaps |

| Pull Bar | Locking planks near walls |

| Level | Checking subfloor evenness |

Mistake 5: Skipping Underlayment When Required

While many SPC vinyl flooring products feature a pre-attached underlayment designed to provide a basic layer of cushioning and sound reduction, there are instances where additional underlayment is necessary. Skipping the installation of underlayment when required can lead to several issues, including a harder surface feel, increased noise transmission, and even potential warranty voidance from the manufacturer.

Why It Matters:

Underlayment serves multiple important purposes. It enhances comfort by softening the feel underfoot, improves sound insulation by reducing the impact noise (such as footsteps), and provides an extra barrier against moisture when installed over certain subfloors. Without proper underlayment, the flooring might feel cold and hard, and noise levels can increase, especially in multi-story buildings or apartments.

Additionally, certain subfloors—like concrete slabs or uneven plywood—may require specialized underlayment materials to provide moisture protection or leveling benefits. Ignoring this step can cause premature wear, damage locking mechanisms, or result in noticeable floor imperfections.

How to Avoid:

- Review Manufacturer’s Instructions Carefully: Always start by checking the flooring brand’s installation manual. They will specify if additional underlayment is needed based on your specific subfloor type.

- Choose Compatible Underlayment: Use underlayment products designed specifically for SPC vinyl flooring to ensure compatibility. Avoid generic or incompatible pads that may react chemically or physically with your flooring.

- Consider the Subfloor Type: Concrete subfloors usually require a moisture barrier underlayment, while wooden subfloors may benefit from padding that evens out minor irregularities.

- Check Warranty Conditions: Some manufacturers require certain underlayment installation to keep warranties valid.

Taking the time to choose and install the right underlayment can improve your flooring’s comfort, acoustics, and lifespan.

Mistake 6: Installing in Unsuitable Areas

SPC vinyl flooring is widely praised for its waterproof, durable, and dimensionally stable properties, making it suitable for many spaces including kitchens, bathrooms, and basements. However, it is important to recognize that it is not designed for every environment.

Installing SPC flooring in unsuitable areas can lead to fading, warping, or damage that undermines the investment and appearance of your floor over time.

Why It Matters:

Certain environments expose flooring to conditions beyond what SPC vinyl flooring can handle:

- Extreme Temperatures: Areas with rapid or extreme temperature swings—like unheated garages or sunrooms—may cause the floor to expand and contract excessively, leading to gaps or buckling.

- Prolonged Direct Sunlight: Excessive UV exposure can cause discoloration or fading of the flooring surface, impacting aesthetics.

- Constant Heavy Moisture: While SPC is waterproof, areas with standing water or constant heavy moisture (such as saunas or outdoor patios) may eventually damage flooring adhesives or underlayers and promote mold growth beneath.

How to Avoid:

- Avoid Problematic Areas: Do not install SPC vinyl flooring in locations prone to direct weather exposure, such as outdoor patios, or extreme environments like saunas.

- Control Sunlight Exposure: Use UV-protective window treatments such as blinds, shades, or films in sun-exposed rooms to minimize discoloration and temperature extremes.

- Assess Moisture Risks: If installing in a basement or high-humidity area, ensure proper vapor barriers and subfloor moisture control measures are in place.

- Consult Manufacturer Guidance: Some brands may offer special SPC products with enhanced UV or moisture resistance—consider these if you must install in challenging areas.

Understanding the limits of SPC vinyl flooring’s environment tolerance will help you choose the right places for installation and maintain the floor’s long-term appearance.

Mistake 7: Rushing Through the Installation Process

A rushed installation is a common but costly mistake that can severely impact both the look and performance of SPC vinyl flooring. Hurrying to finish the project often leads to cutting errors, misaligned planks, poorly engaged locking mechanisms, and overlooked critical steps such as expansion gaps or subfloor inspections.

Why It Matters:

The precision and patience taken during installation directly affect the floor’s durability, appearance, and warranty coverage. An improper installation may cause immediate visible issues or problems that develop over time, including:

- Loose or popping joints

- Visible gaps between planks

- Buckling or warping

- Premature wear and tear

- Voided manufacturer warranties

How to Avoid:

- Plan and Prepare Thoroughly: Before starting, gather all tools, review installation instructions, and prepare the work area.

- Measure Twice, Cut Once: Accurate measurements and cuts reduce waste and prevent plank misalignment.

- Use Proper Techniques: Engage locking mechanisms carefully and verify that planks are tightly connected without forcing them.

- Work in Sections: Install flooring methodically, section by section, ensuring each row is properly laid before moving on.

- Allow Adequate Time: Set realistic timelines for the project, avoiding pressure to rush.

- Seek Professional Help When Needed: If uncertain about any installation step, consult a professional installer or watch trusted tutorial videos to ensure quality.

Patience and attention to detail are critical. Taking your time ensures a floor that looks flawless and lasts for years.

Conclusion

Avoiding these seven critical mistakes can significantly increase the success rate of your SPC vinyl flooring project. Each step in the installation process plays a vital role in the longevity and functionality of the floor. From subfloor preparation to proper tool usage, being mindful of every detail ensures that your flooring not only looks great but performs exceptionally for years.

If you’re considering SPC vinyl flooring for your space, learning from common installation errors is the first step toward a durable and beautiful floor.

FAQ

Can I install SPC vinyl flooring over existing tile?

Yes, as long as the tile is in good condition, flat, and clean. Uneven tiles should be leveled first.

Do I need to seal SPC vinyl flooring?

No. SPC vinyl flooring is already waterproof and does not require sealing.

How do I clean SPC vinyl flooring after installation?

Use a damp mop and pH-neutral cleaner. Avoid harsh chemicals and abrasive scrubbers.

Can I use SPC vinyl flooring in a bathroom?

Yes, SPC vinyl flooring is waterproof and suitable for bathrooms, provided it’s installed correctly.

What should I do if my SPC vinyl flooring starts creaking?

Check for uneven subflooring or insufficient expansion gaps. If necessary, lift the floor and correct the problem before reinstalling.