Welcome to My Blog! 🌟

Before we dive into the content, let’s stay connected! Join me on my social media platforms where I share exclusive insights, engage with our amazing community, and post regular updates. Here’s how you can connect with me:

📘 Facebook: Follow Me on Facebook

Now, let’s embark on this journey together. I hope you find the content here insightful, engaging, and most importantly, valuable. Let’s explore, learn, and grow together! 🚀

Feel free to share your thoughts and feedback in the comments or on my social media—I’d love to hear from you! 😊

Table of Contents

Introduction

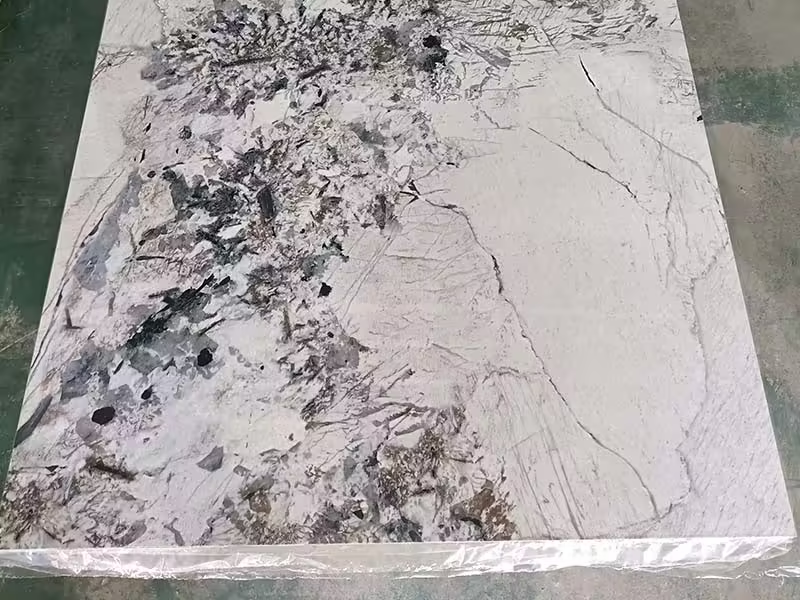

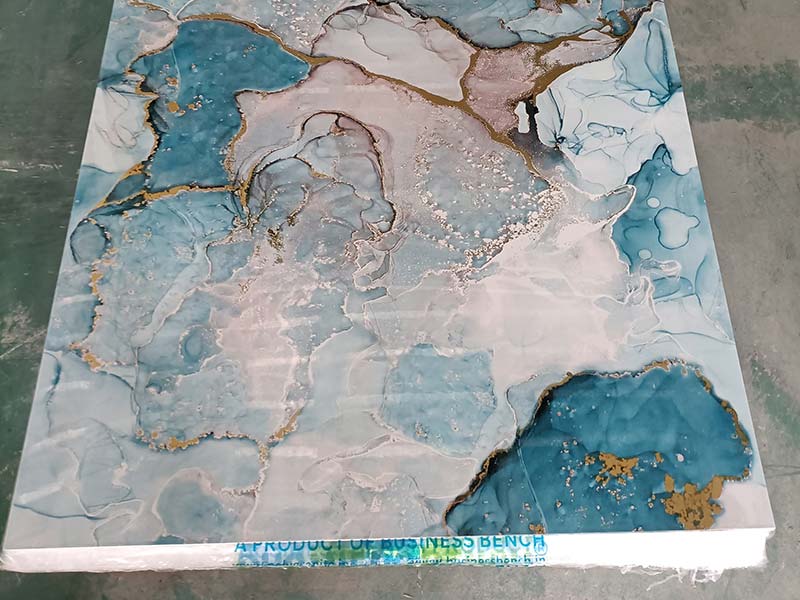

Marble PVC sheet has become a popular alternative to natural stone due to its cost-effectiveness, elegant appearance, and installation simplicity. Combining the timeless look of marble with the functionality of plastic polymers, it is widely used in residential and light commercial interiors. However, many buyers end up overpaying for marble PVC sheet without realizing it. Whether you’re a contractor, designer, or individual renovator, understanding the true value behind pricing can save you significant money and frustration.

In this blog by Shandong Panel International Trade Co., Ltd., we reveal six warning signs that you might be overpaying for your marble PVC sheet purchase and guide you on how to make informed, budget-wise decisions.

Sign 1: You’re Paying for Brand Instead of Quality

Many buyers assume that a higher price always guarantees better materials or durability. However, in the decorative panel industry, this assumption is often false. A significant portion of the marble pvc sheet cost in branded offerings may come from excessive marketing, distribution channels, or simply brand name premiums—rather than the actual manufacturing quality or material innovation.

How to Evaluate True Value:

- Compare Specifications, Not Just Brands: Instead of relying solely on a brand’s reputation, dig deeper into technical details. Check the exact thickness of the sheet, the density and grade of the PVC resin used, the quality of UV coatings, and surface finishing. These concrete parameters provide a more accurate reflection of performance and durability.

- Request a Material Test Report (MTR): Reputable manufacturers will provide detailed MTRs demonstrating product performance in critical areas like flame retardancy, scratch resistance, waterproofing, and UV stability. These objective test results help you understand what you are paying for and separate marketing hype from genuine product capability.

- Look for Certification Proof: Industry certifications such as ISO 9001 quality management, SGS testing reports, or CE compliance demonstrate a commitment to standardized manufacturing and safety practices. These certificates often carry more weight than a brand logo when judging product reliability.

Investing in a well-manufactured marble pvc sheet from a capable supplier—rather than paying for brand markup—can significantly reduce your cost per square meter without sacrificing performance.

Sign 2: No Transparency in Specification or Material Source

One of the clearest warning signs that you’re overpaying is lack of transparency. If your supplier can’t clearly tell you the source of their PVC resin, the structure of the UV coating, or even the actual thickness, you might be charged a premium for subpar goods.

Key Factors to Confirm:

- Exact Thickness: Common options include 2mm, 2.5mm, 3mm, and 3.8mm. Thicker sheets generally offer better strength and longevity.

- UV Coating Quality: A genuine UV-coated marble pvc sheet should resist yellowing, fading, and surface scratches in indoor environments.

- PVC Resin Grade: Virgin resin is preferred over recycled materials for structural consistency and environmental safety.

If your supplier is vague or avoids answering direct technical questions, consider it a red flag. Reliable partners like Shandong Panel International Trade Co., Ltd. are proud to disclose full specifications, backed by test reports and manufacturing documentation.

Sign 3: Installation and Maintenance Not Included in Cost

The unit price of a marble pvc sheet may seem attractive at first glance, but that’s only a portion of your real investment. Many buyers forget to calculate installation costs and future maintenance, both of which can quickly inflate the total expense if not accounted for.

Hidden Costs to Watch:

- Installation Tools: Adhesives, surface preparation materials, or additional structural support for uneven walls.

- Wear and Tear: Depending on finish quality, cheap panels may scratch or stain more easily, requiring early replacement.

- Cleaning Requirements: High-gloss UV-coated sheets are generally easier to clean, but some materials may need polishing or scratch fillers.

When choosing your supplier, ask if they provide installation guides, recommended adhesives, or even technical consultation—as we do at Shandong Panel International Trade Co., Ltd. This ensures you avoid unexpected costs after your initial purchase.

Sign 4: No Value-Added Services or Customization

Customization is often essential for modern interior decoration projects. If you’re paying extra for every small change—such as custom size, texture, or design adaptation—you’re not getting optimal value from your supplier.

What Real Value Should Include:

- Custom Size & Color Matching: A reliable supplier should accommodate custom project needs without excessive fees.

- OEM/ODM Capability: Suppliers that offer original design and manufacturing services can often optimize production for large-volume orders.

- Pre-Sale Technical Support: The ability to provide advice on panel selection, fire safety classifications, or recommended use cases adds significant value.

Shandong Panel International Trade Co., Ltd. integrates R&D and production, allowing us to deliver highly customized marble pvc sheet solutions without passing excessive costs onto the customer.

Sign 5: Poor Warranty or After-Sales Support

You Even the most carefully selected marble pvc sheet can run into issues—whether during transport, installation, or early use. If your product isn’t backed by a proper warranty, those risks turn into additional costs.

What You Should Expect:

- Minimum One-Year Warranty: Covers warping, surface defects, peeling, and UV coating failure under normal use.

- Online Technical Support: Should be available to assist with installation questions, defect reports, and best practices.

- Return/Replacement Policy: Clarify whether defective goods can be returned or exchanged without unreasonable delays or expenses.

Suppliers who hesitate to offer post-sale guarantees are often cutting corners on materials or manufacturing quality. At Shandong Panel International Trade Co., Ltd., we offer a one-year product warranty and comprehensive online support, giving you peace of mind from start to finish.

Sign 6: You’re Not Comparing Pricing Tiers

Buyers often don’t realize there are different product grades with varying durability, features, and finishes. Comparing apples to oranges can result in overpaying for basic sheets that don’t deliver premium performance.

Use the Following Table as Reference:

| Feature | Basic Marble PVC Sheet | Premium Marble PVC Sheet |

|---|---|---|

| Thickness Options | 2mm | Up to 3.8mm |

| UV Coating | Standard gloss | High-gloss, scratch-proof |

| Durability | Moderate | High |

| Fireproof/Waterproof Level | Basic | Certified Safe |

| Customization Support | Limited | Full OEM/ODM Available |

| Warranty | None or limited | 1-year minimum |

Understanding your needs and aligning them with the right pricing tier helps avoid overpaying.

Conclusion

The marble PVC sheet is a powerful alternative to traditional stone—but only if you make wise purchasing decisions. Avoid the six signs of overpayment by verifying specifications, seeking transparency, comparing product tiers, and demanding service and support.

At Shandong Panel International Trade Co., Ltd., we are proud to deliver high-quality, competitively priced decorative materials with complete support throughout the supply chain. Our PVC UV marble sheets are waterproof, fireproof, eco-safe, and customized to fit your unique needs.

Looking for the best value? Contact our team for a free sample, technical advice, or custom quote today.

FAQ

What is the standard size of a marble PVC sheet?

The most commonly used size is 1220 x 2440 mm, which fits most wall and panel applications. However, we support custom sizes based on specific project requirements, allowing you to achieve seamless installation and visual consistency.

What thickness options are available?

We offer thicknesses ranging from 2mm to 3.8mm. Thicker panels provide superior durability and surface stability, making them suitable for high-traffic or commercial environments.

Are marble PVC sheets waterproof and fireproof?

Yes, our marble pvc sheets are both waterproof and fire-resistant. These properties make them ideal for moisture-prone areas like kitchens and bathrooms, as well as for commercial interior applications where safety is critical.

Can I install them myself?

Absolutely. Our sheets are designed for easy installation using standard construction adhesives or glue. We also provide installation manuals and expert tips to guide you through the process, ensuring optimal results even with DIY applications.

Is customization available?

Yes. Shandong Panel International Trade Co., Ltd. offers comprehensive OEM/ODM services, including custom colors, sizes, surface textures, and branding. Whether you need a bold marble pattern or a subtle finish, we can tailor the solution to your vision.