Welcome to My Blog! 🌟

Before we dive into the content, let’s stay connected! Join me on my social media platforms where I share exclusive insights, engage with our amazing community, and post regular updates. Here’s how you can connect with me:

📘 Facebook: Follow Me on Facebook

Now, let’s embark on this journey together. I hope you find the content here insightful, engaging, and most importantly, valuable. Let’s explore, learn, and grow together! 🚀

Feel free to share your thoughts and feedback in the comments or on my social media—I’d love to hear from you! 😊

Table of Contents

Introduction

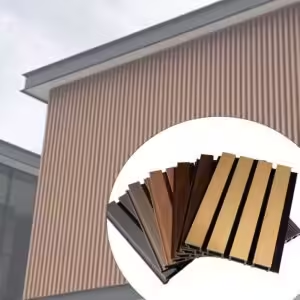

WPC panels exterior applications are increasingly becoming the go-to choice for builders, architects, and homeowners seeking a blend of durability and aesthetic appeal. WPC, or wood-plastic composite, panels are known for their resistance to moisture, UV exposure, and temperature changes, making them ideal for outdoor use. The unique combination of wood fibers and plastic polymers allows for strength, flexibility, and low maintenance requirements, unlike traditional wood cladding which may warp, rot, or require frequent repainting.

The exterior of a building sets the tone for its architectural style and offers the first impression of its structural integrity. With the increasing demand for eco-friendly and long-lasting materials, the popularity of WPC panels exterior continues to surge. This article provides five proven tips to help you choose, install, and maintain WPC panels for superior exterior performance.

Tip 1: Choose the Right Type of WPC Panels Exterior

When selecting wpc panels exterior products, the first and arguably most important step is understanding the different types available in the market. WPC, or wood-plastic composite, is a hybrid material made from a blend of wood fibers and plastic polymers. Though this may sound simple, not all WPC products are created equal. The differences in material ratios, additives, processing technology, and design features lead to varied results in terms of strength, appearance, and durability.

There are two major structural types of wpc panels exterior:

- Hollow WPC Panels: These are lightweight and easier to transport and install. They are often used in low-traffic areas or for decorative purposes. While they reduce the load on support structures and can offer cost savings, they generally lack the rigidity of their solid counterparts. Their acoustic and impact performance is also lower, which could be a limitation in applications requiring resilience.

- Solid WPC Panels: Solid panels are denser and stronger. They resist deformation, offer superior sound insulation, and withstand heavy usage and harsh weather. These are ideal for exterior applications like facades in high-rise buildings, commercial spaces, or climates with extreme sun, wind, or moisture exposure.

When choosing the right wpc panels exterior, also consider the following performance indicators:

- UV Resistance: Essential for areas with high sunlight exposure. UV-protected panels resist fading and maintain color integrity.

- Water Absorption: Panels with lower absorption rates resist swelling, warping, and mold. This is vital in humid or rainy climates.

- Fire Retardancy: For safety, especially in public buildings or wildfire-prone regions, always check for compliance with local fire rating codes.

Lastly, the wood-to-plastic ratio impacts both appearance and durability. A higher wood content provides a more natural aesthetic but may absorb more moisture. Higher plastic content ensures greater resistance to the elements, though some may feel the texture looks artificial.

Understanding these variations allows you to make an informed decision and choose wpc panels exterior that match both your design vision and performance requirements.

Tip 2: Proper Installation Ensures Long-Term Durability

Even the most advanced wpc panels exterior cannot reach their full potential without proper installation. In fact, incorrect installation is one of the leading causes of early failure or performance degradation in composite cladding systems.

Start by building a robust substructure. This framework is typically made of galvanized steel, aluminum, or pressure-treated timber battens. The choice of material depends on the location’s climate and expected load. Galvanized steel and aluminum are rust-resistant and long-lasting, making them ideal for coastal or humid zones.

Before installation, wpc panels exterior should be acclimated to the local environment for at least 48 hours. This helps the material adjust to temperature and humidity conditions, reducing the risk of sudden contraction or expansion post-installation.

When fixing the panels:

- Use stainless steel screws or composite-compatible fasteners to avoid corrosion and cracking.

- Maintain consistent spacing between panels to allow for thermal expansion. Generally, a 5-8 mm gap is sufficient.

- Employ hidden fastener systems for a sleek, seamless finish and enhanced water resistance.

Ignoring these practices can lead to panel warping, surface buckling, or water intrusion. Following detailed manufacturer instructions or hiring trained installers ensures that wpc panels exterior deliver on their promises for years to come.

Moreover, ensure proper ventilation behind the panels. A ventilated facade design, often achieved by leaving an air gap between the panel and insulation layer, prevents moisture build-up and improves energy efficiency.

Tip 3: Compare WPC Panels Exterior by Key Performance Metrics

Before making a final decision on which WPC panels exterior product to choose, it helps to compare several options based on essential performance indicators. These include weather resistance, maintenance needs, lifespan, appearance, and price.

Here is a table to help you evaluate common WPC panels exterior choices:

| Feature | Solid WPC Panels | Hollow WPC Panels | Natural Wood Cladding |

|---|---|---|---|

| Weather Resistance | Excellent | Good | Poor to Moderate |

| Maintenance | Low | Low | High |

| Aesthetic Appearance | Natural Look | Moderate Look | Authentic Wood |

| Lifespan | 20+ Years | 10-15 Years | 5-10 Years |

| Installation Cost | Moderate to High | Low to Moderate | High |

The table illustrates that while natural wood may offer a classic look, WPC panels exterior outperform in virtually every other aspect. Their blend of performance and minimal upkeep makes them ideal for modern buildings and eco-conscious projects.

Tip 4: Maintain WPC Panels Exterior with Simple Care

One of the top reasons designers and contractors choose wpc panels exterior is their low-maintenance nature. Unlike traditional wood that demands frequent painting, sealing, and pest control, WPC cladding requires only basic care to stay in top condition.

For routine upkeep:

- Regular Cleaning: Rinse panels with water to remove dust and pollen. For more stubborn grime, use a sponge or soft-bristle brush with diluted soap.

- Avoid Harsh Chemicals: Cleaners containing bleach or acetone may erode the surface or fade the color. Stick to pH-neutral or WPC-recommended products.

- Prevent Pressure Washing: High-pressure streams can damage surface textures or force water into connection joints.

Periodic inspections, ideally once per season, help detect early signs of wear or damage. Look for:

- Loose fasteners

- Cracks near edges

- Discoloration from UV exposure

- Mold or algae buildup in shaded or damp areas

If necessary, touch-up products are available to restore surface color or sheen. Some manufacturers also offer UV-blocking sealants that can be reapplied every few years to enhance longevity and preserve appearance.

By implementing these simple care steps, wpc panels exterior can maintain their form and function for decades, offering peace of mind and visual appeal without the traditional maintenance burden.

Tip 5: Optimize Design for Functionality and Style

The versatility of wpc panels exterior extends far beyond simple wall cladding. With advancements in manufacturing, these panels now come in various colors, textures, and formats, enabling architects and homeowners to get creative with building exteriors.

Design options include:

- Horizontal or Vertical Paneling: Horizontal lines evoke a modern, grounded look, while vertical layouts can make buildings appear taller and more elegant.

- Mixed Textures and Colors: Alternating panels of smooth and embossed finishes, or using contrasting colors, can create dynamic facades that catch the eye.

- Slat and Louver Designs: These not only offer visual interest but also improve ventilation and can act as solar shading systems.

Functionally, wpc panels exterior also improve building envelope performance. When used alongside external insulation systems, they help reduce energy loss by blocking wind and UV radiation. This can lower heating and cooling costs, supporting green building certifications and improving indoor comfort.

Applications extend to:

- Soffits and Fascia Boards

- Balcony Ceilings

- Privacy Screens

- Outdoor Kitchens and Pergola Cladding

By integrating wpc panels exterior into both structural and decorative elements, you enhance not only aesthetics but also performance. The result is a seamless combination of design creativity and engineering function.

Conclusion

WPC panels exterior present a compelling solution for modern exterior cladding, combining strength, aesthetics, and sustainability. From selecting the right type to ensuring precise installation and easy upkeep, these five proven tips offer a practical guide for anyone considering WPC panels.

By understanding the key attributes of WPC materials and planning strategically, builders and homeowners can achieve long-lasting, visually appealing exteriors that withstand the test of time.

Whether you are revamping an old facade or starting from scratch, WPC panels exterior are a forward-thinking choice that adds value and style.

FAQ

Q1: Are WPC panels exterior weatherproof?

Yes, most WPC panels are highly resistant to rain, sun, and temperature changes, making them ideal for outdoor applications.

Q2: Can I paint WPC panels exterior?

It is not recommended to paint them, as they are designed with built-in color layers. Painting may void warranties and affect longevity.

Q3: How long do WPC panels exterior last?

High-quality WPC panels can last over 20 years with minimal maintenance, depending on environmental conditions and installation.

Q4: Are WPC panels environmentally friendly?

Yes, they are made from recycled wood fibers and plastics, reducing the need for virgin wood and contributing to sustainable building practices.

Q5: What tools are needed to install WPC panels exterior?

Basic woodworking tools, composite fasteners, a level, and protective gear are typically sufficient for proper installation.